Ripmax Xcalibur Sports jet

#2351

Thread Starter

Tone

The horns screw on with self tapping screws, there is a half moon plywood plate in all surfaces. The small looking PK screws are used to screw them on and are more than adequate proved by hundreds of flights. If you iron the film before installing you can see the ply outline

The horns screw on with self tapping screws, there is a half moon plywood plate in all surfaces. The small looking PK screws are used to screw them on and are more than adequate proved by hundreds of flights. If you iron the film before installing you can see the ply outline

#2352

Tone

The horns screw on with self tapping screws, there is a half moon plywood plate in all surfaces. The small looking PK screws are used to screw them on and are more than adequate proved by hundreds of flights. If you iron the film before installing you can see the ply outline

The horns screw on with self tapping screws, there is a half moon plywood plate in all surfaces. The small looking PK screws are used to screw them on and are more than adequate proved by hundreds of flights. If you iron the film before installing you can see the ply outline

thanks,

Tone

#2353

The inspectors here wont sign off on the jet here if I only screw them on from one side, that is for sure, even if I tell them it works fine everywhere else :-)

I also bought mine from Lindinger, and a friend also, and we are both missing our 3 mm control clevises. Are they included in your kit ?

I also bought mine from Lindinger, and a friend also, and we are both missing our 3 mm control clevises. Are they included in your kit ?

#2354

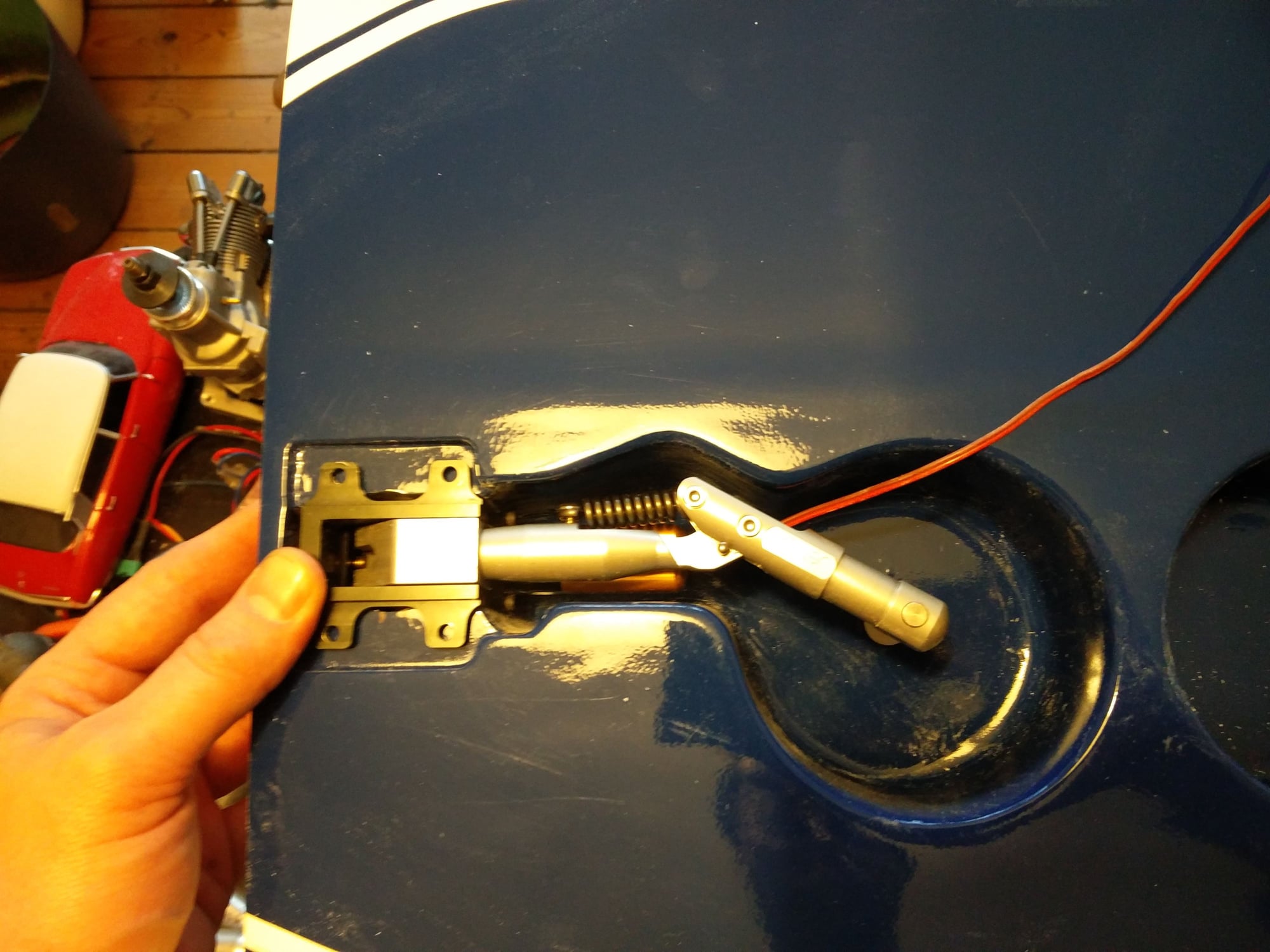

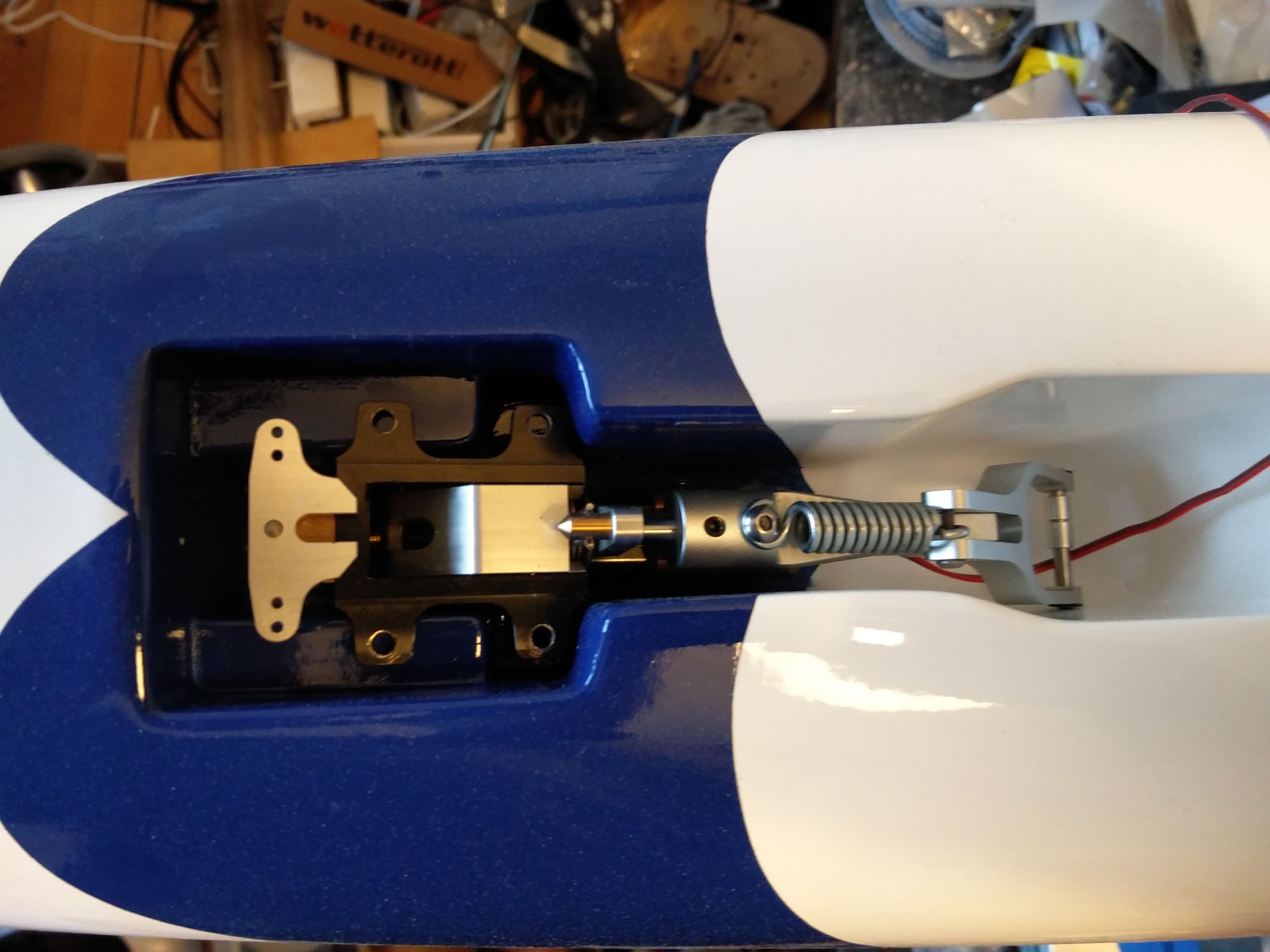

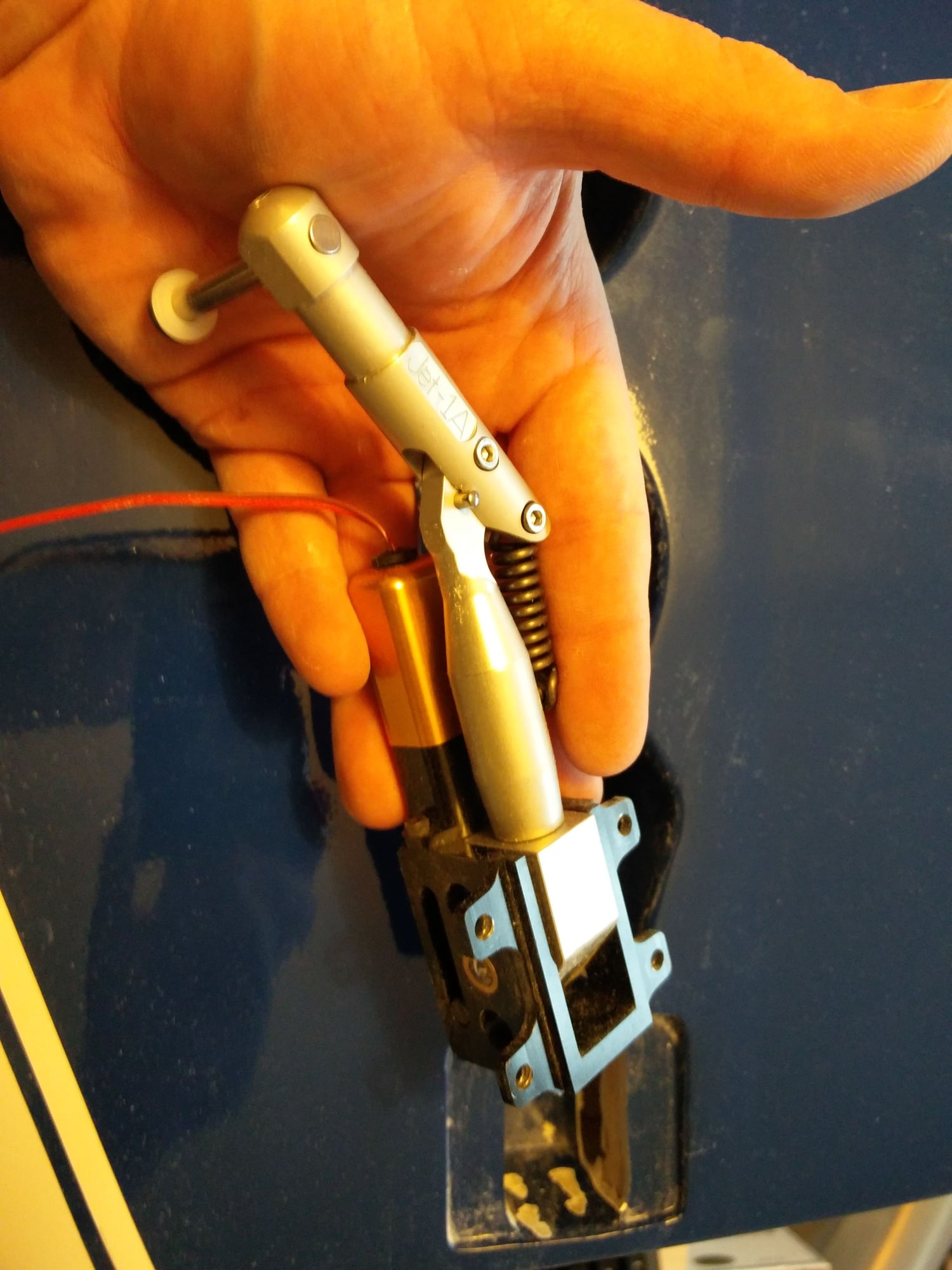

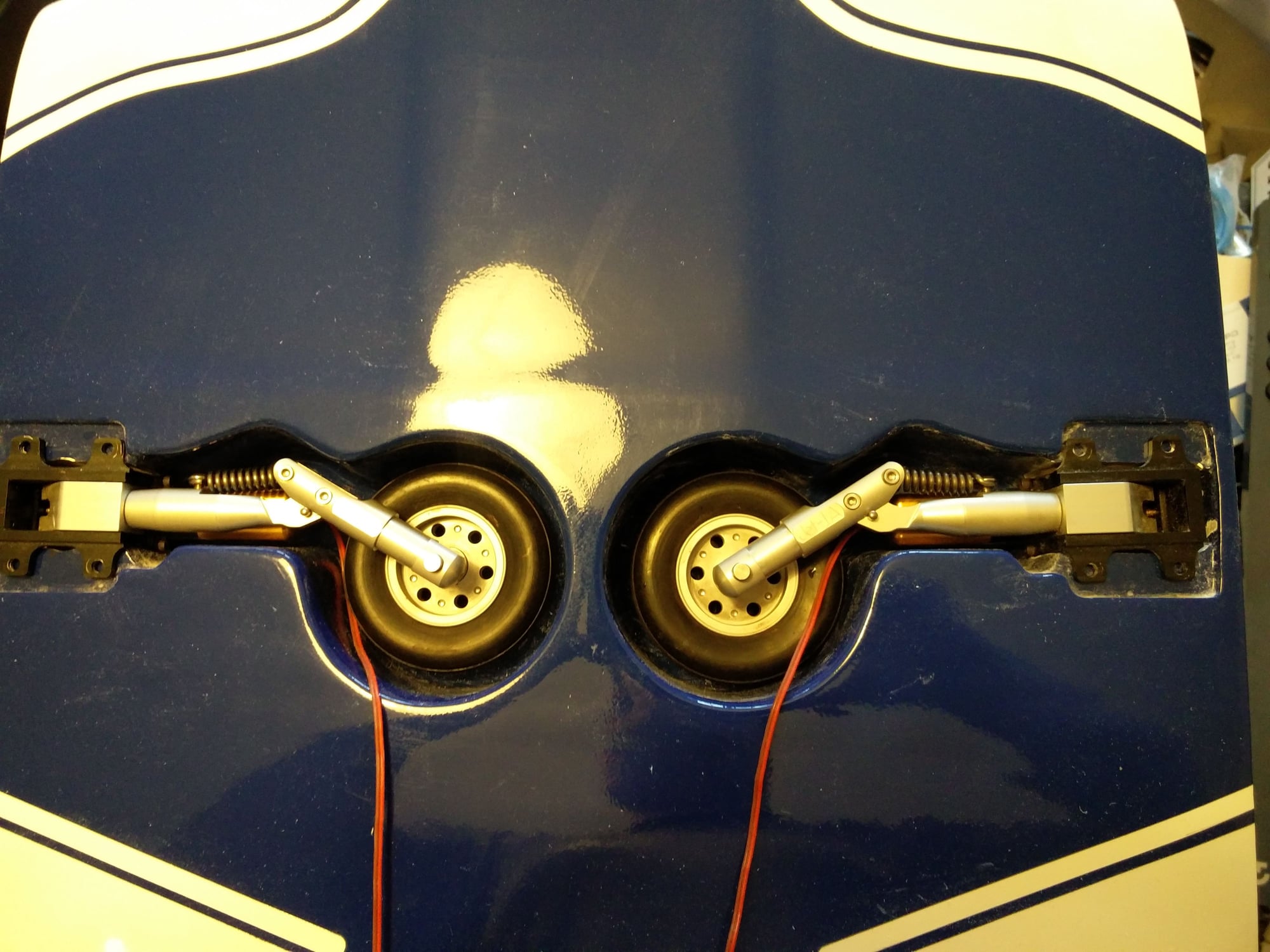

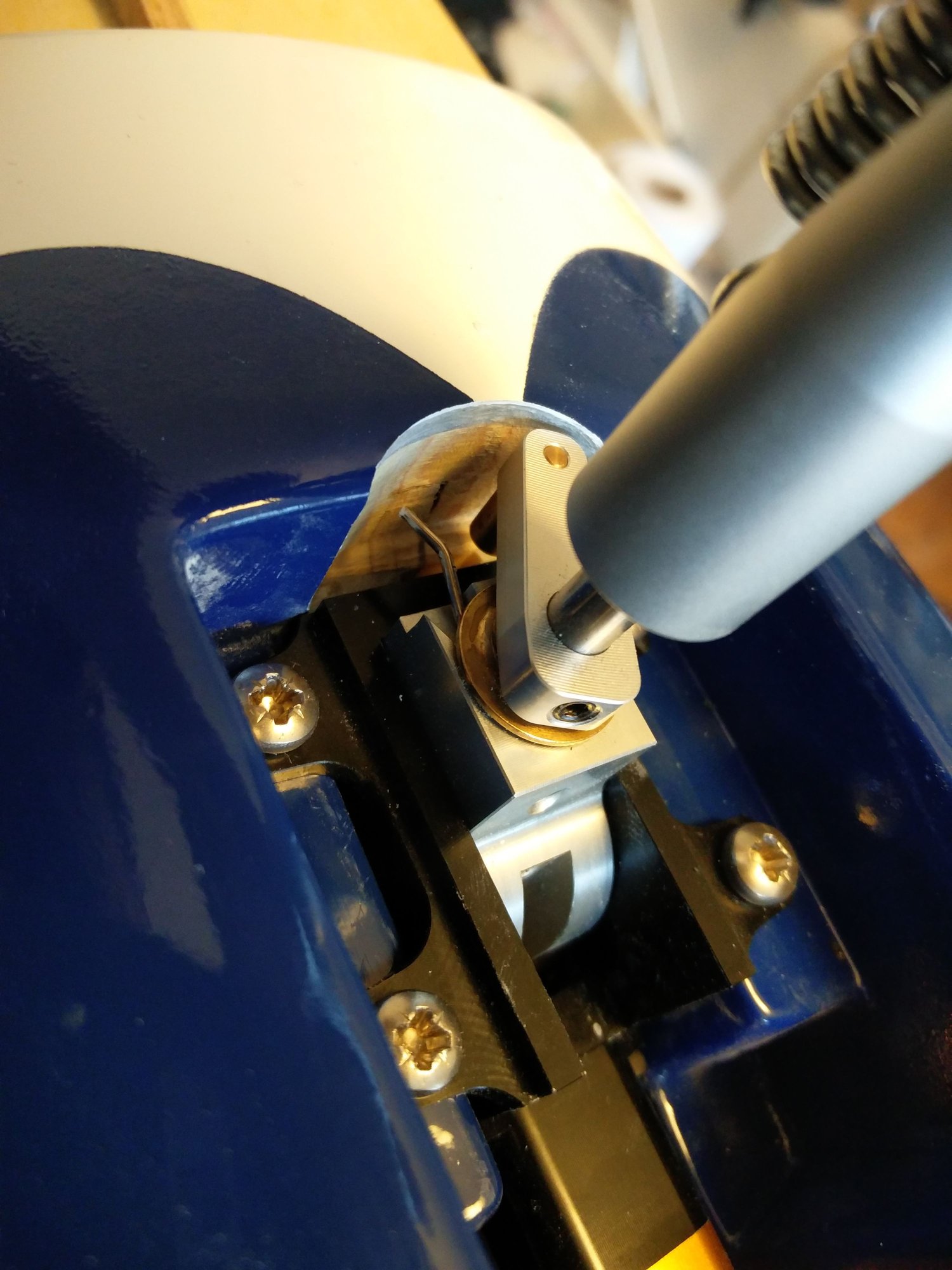

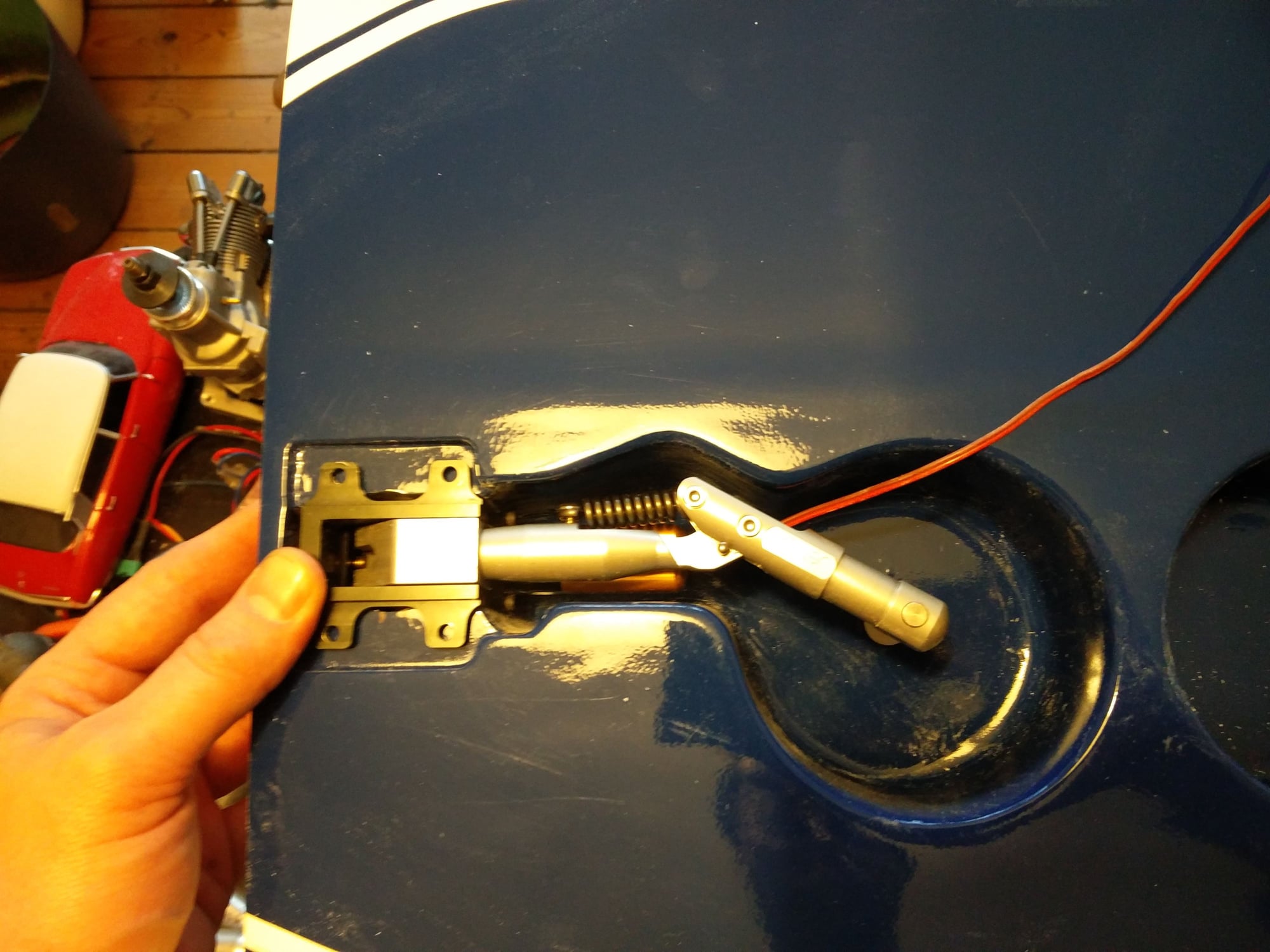

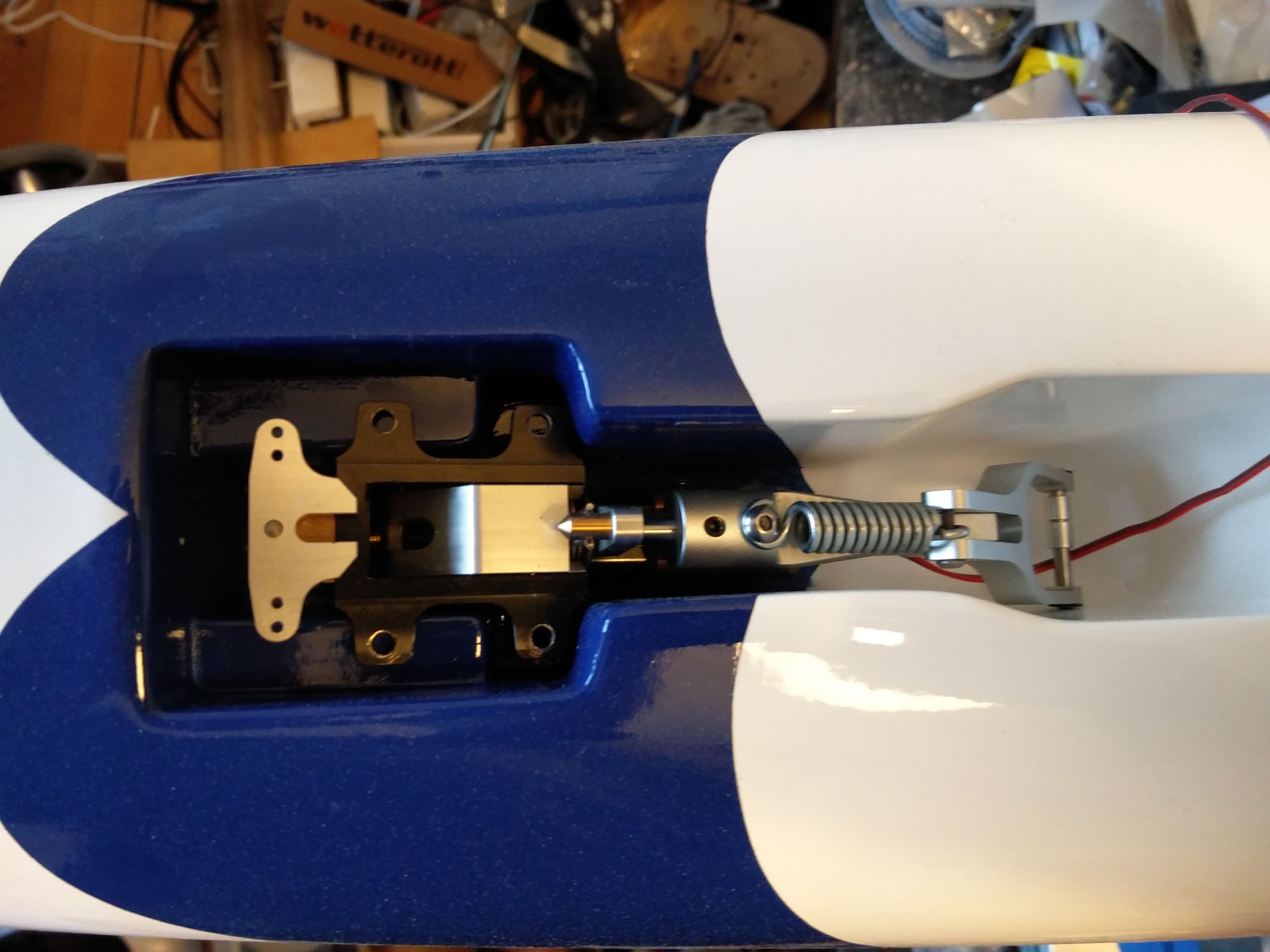

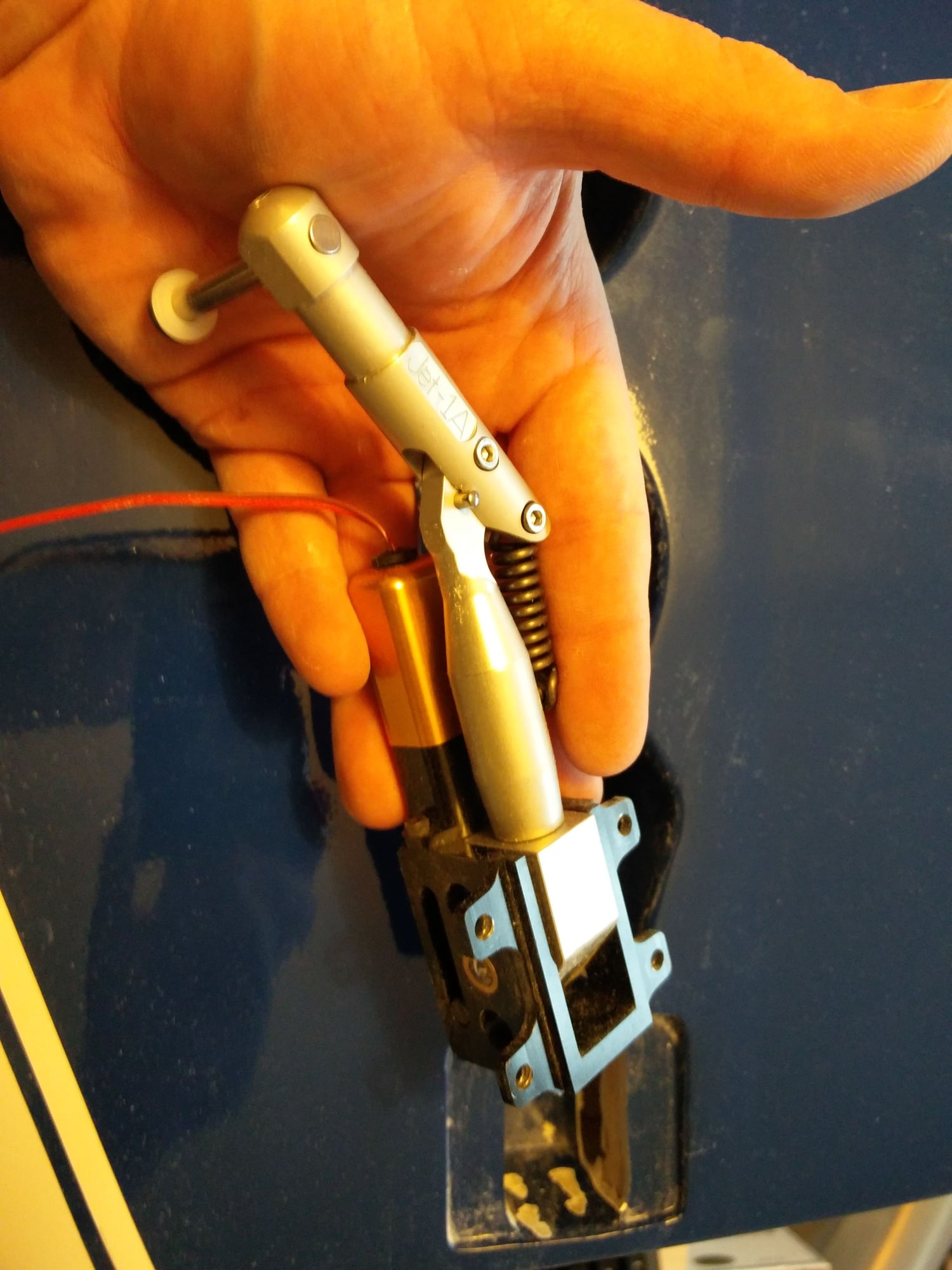

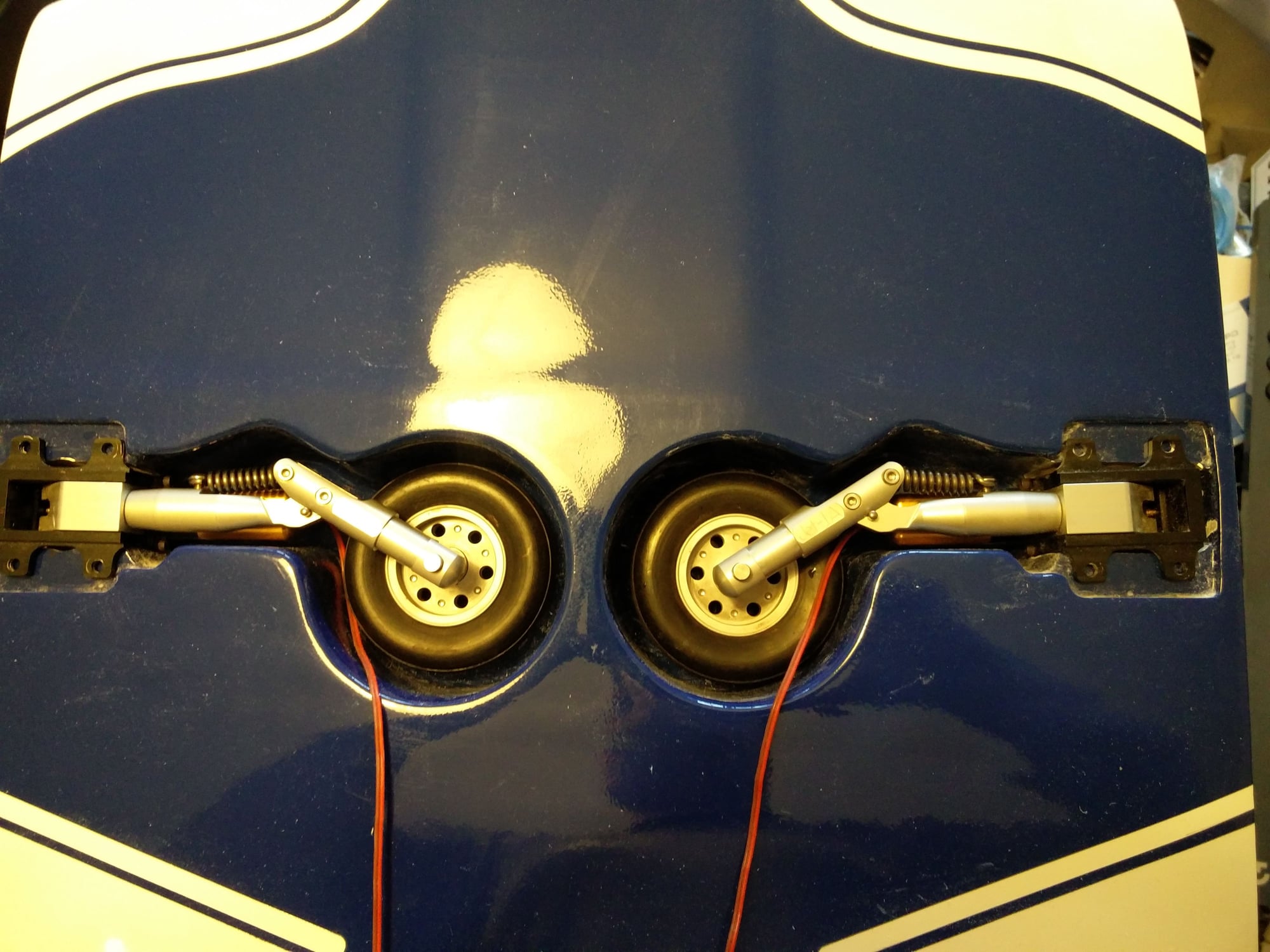

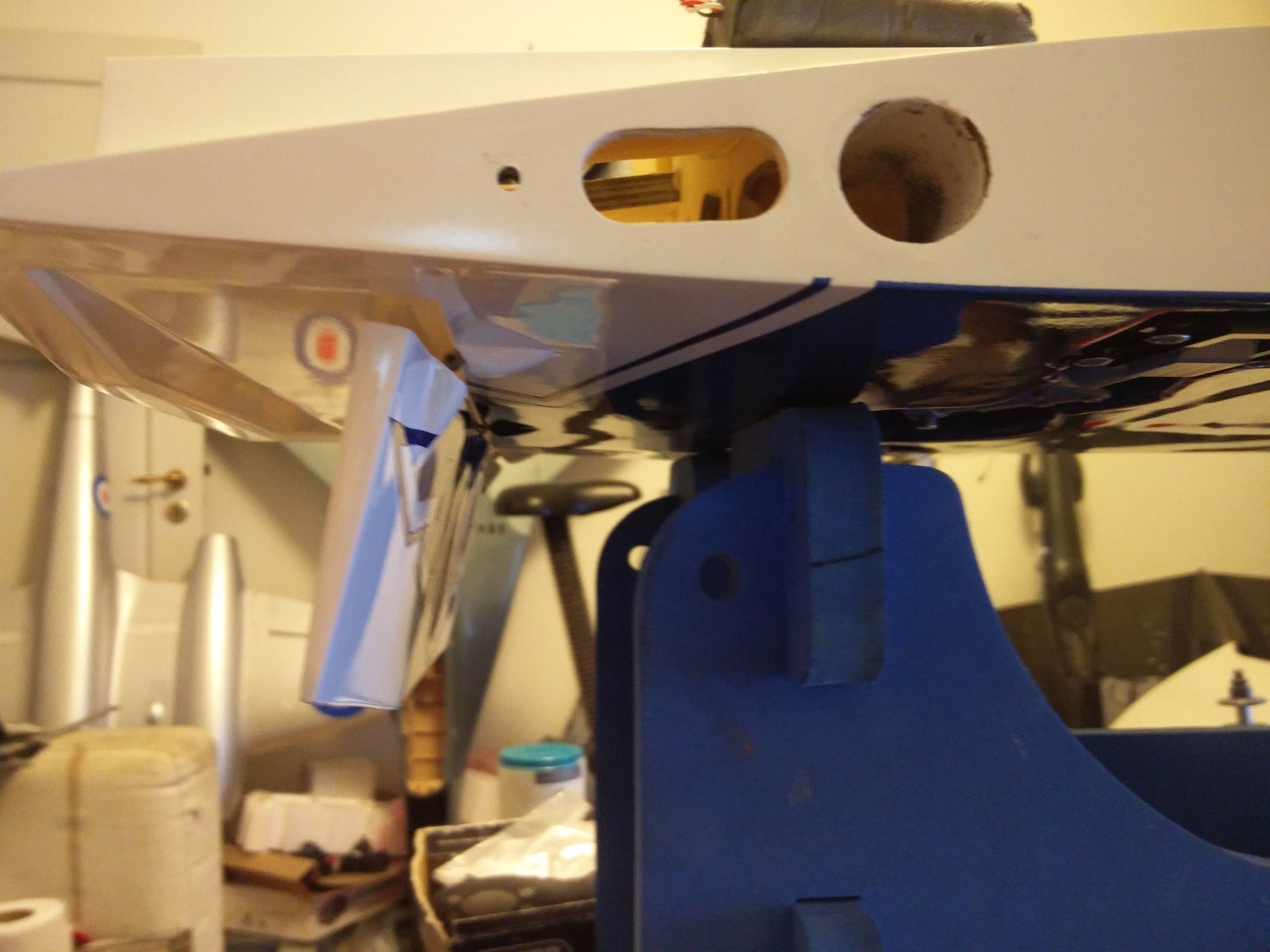

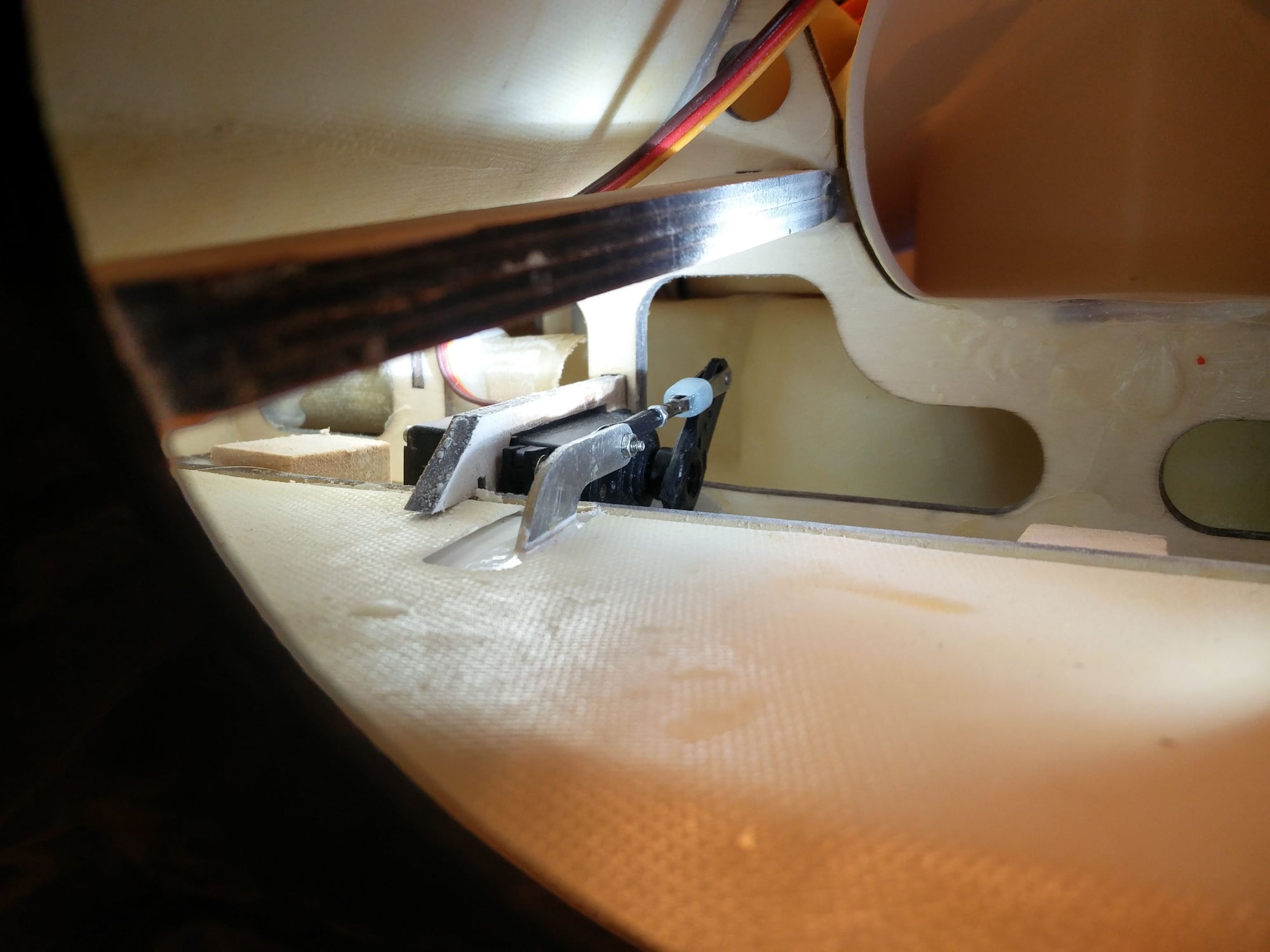

Got my Jet-A1 main retracts today from https://www.jautsch.de/ , so Now I can begin the install.

Im using the original ripmax nosegear. They will be installed in original CYS R2090 retract units :-)

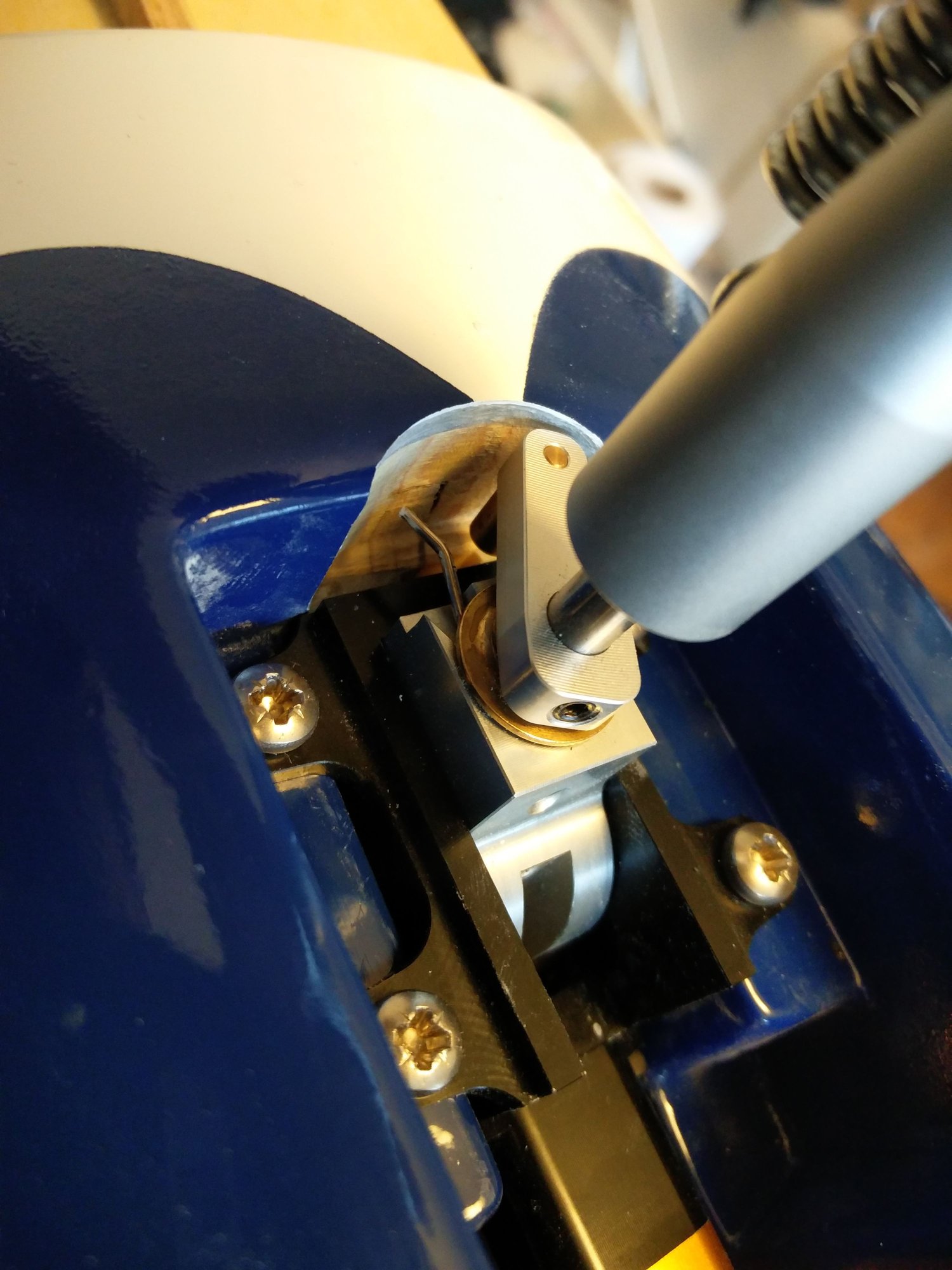

They are 2mm too wide , so I had to dremel out the bays width. The nose gear also has a centering pin, that I had to make room for.

I have removed the original steering system, and have ordered a normal metal horn with 6mm hole in it to fin on the nose leg connecting pin.

Im using the original ripmax nosegear. They will be installed in original CYS R2090 retract units :-)

They are 2mm too wide , so I had to dremel out the bays width. The nose gear also has a centering pin, that I had to make room for.

I have removed the original steering system, and have ordered a normal metal horn with 6mm hole in it to fin on the nose leg connecting pin.

#2355

The inspectors here wont sign off on the jet here if I only screw them on from one side, that is for sure, even if I tell them it works fine everywhere else :-)

I also bought mine from Lindinger, and a friend also, and we are both missing our 3 mm control clevises. Are they included in your kit ?

I also bought mine from Lindinger, and a friend also, and we are both missing our 3 mm control clevises. Are they included in your kit ?

My kit did not come with the 3mm clevis either. I contacted Lindinger and they sent me some threaded 3mm rod and ball links.

thanks,

Tone

Last edited by Agrav8ed; 02-19-2019 at 08:48 AM. Reason: Spelling

#2356

That was nice of them :-)

I just bought some at the local hobby shop.

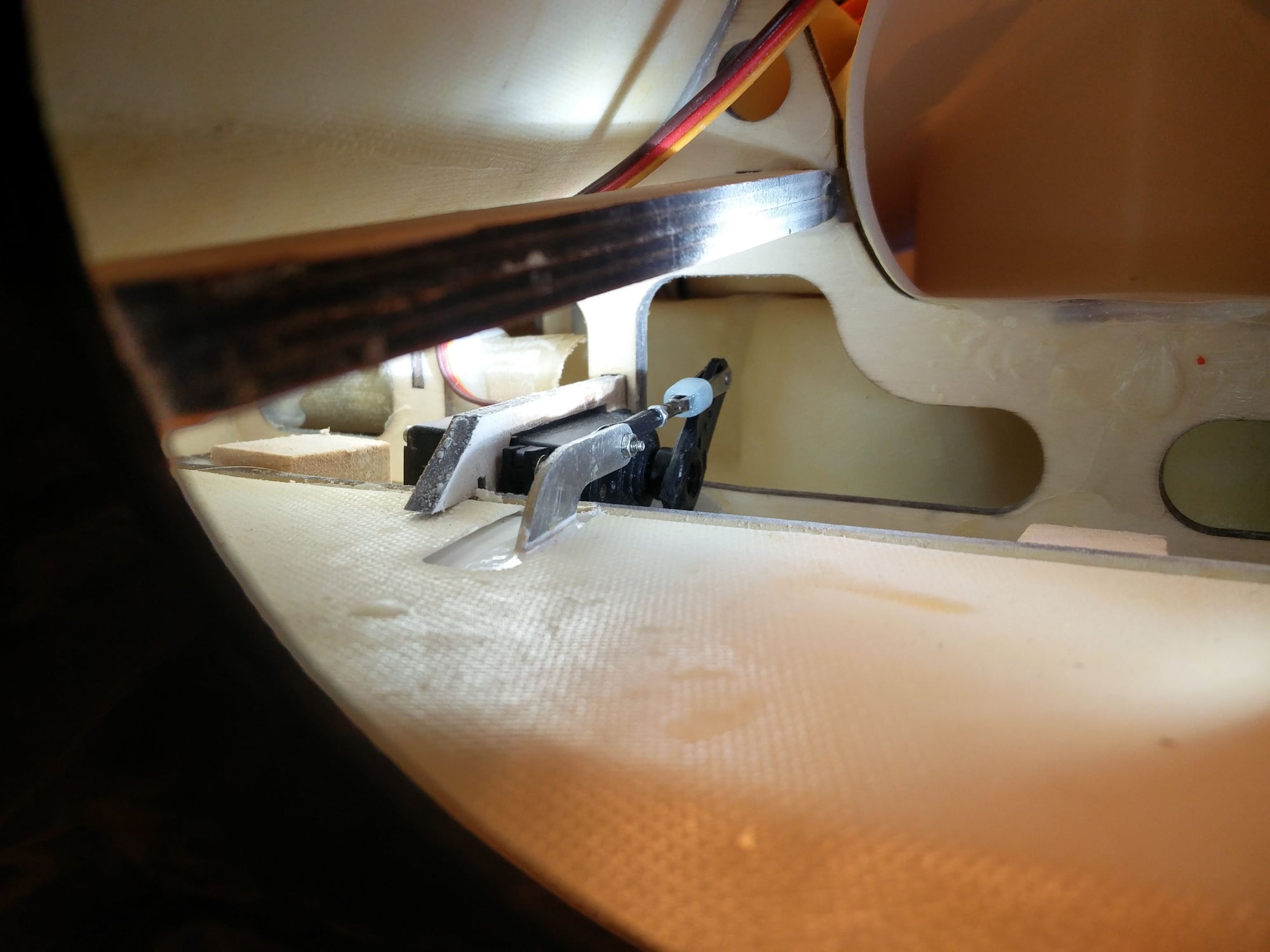

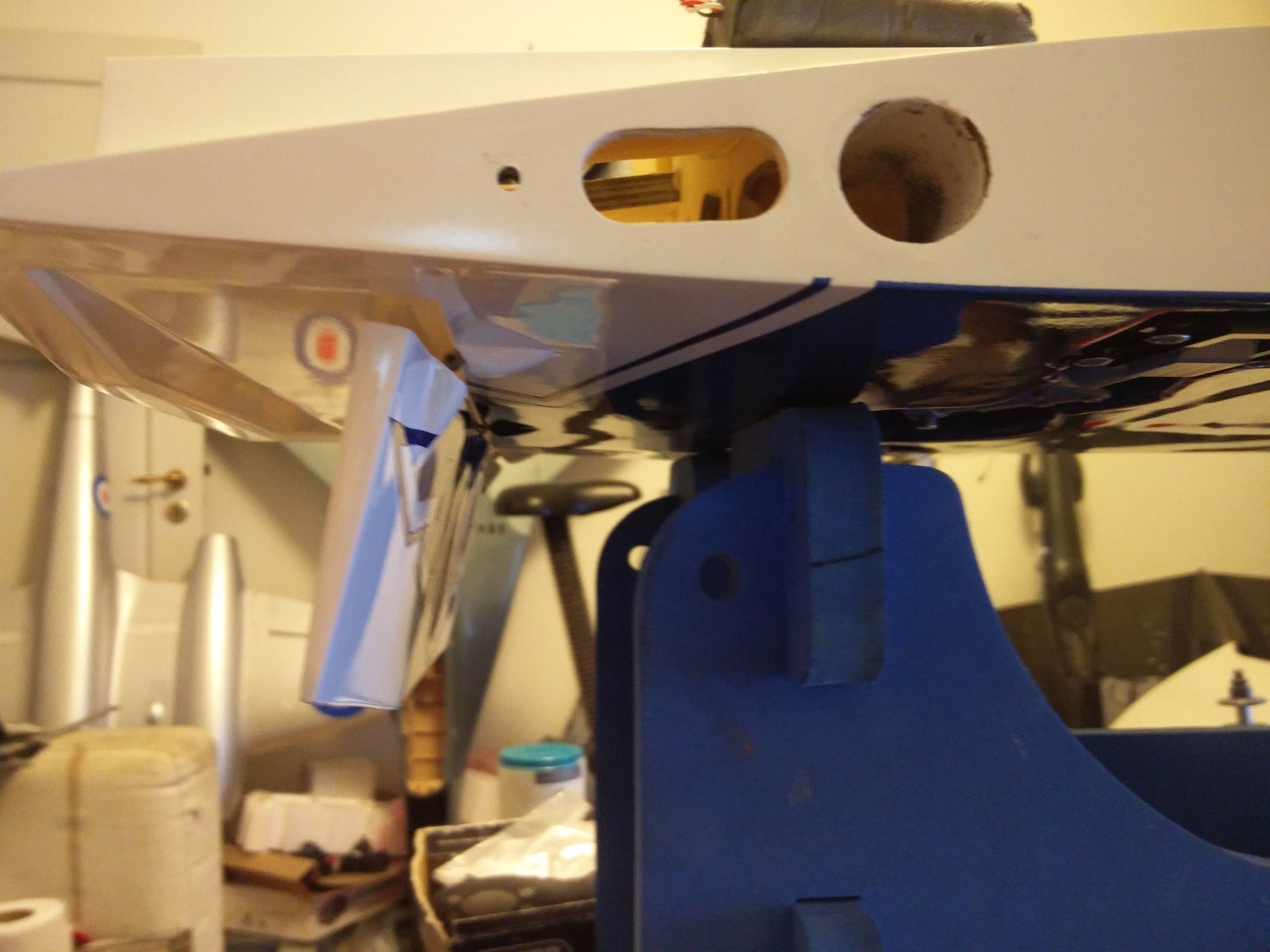

Got my flap/airbrake done.

With the right tools on hand its easy

Man....these big images are annoying.....is there a way to get them to show as thumbnails like before ?

I just bought some at the local hobby shop.

Got my flap/airbrake done.

With the right tools on hand its easy

Man....these big images are annoying.....is there a way to get them to show as thumbnails like before ?

#2358

When we are mounting the turbine how high does it have to be to match the intake duct? Will all four blocks be enough? The manual states to mount it centerline of the intake duct but the duct is not round so I am a bit confused. Can anyone who has built one give me some advice? I am using a Swiwin 80.

thanks

Tone

thanks

Tone

#2359

My Feedback: (24)

Hi All, I’m finally finishing up my Xcalibur, it’s one of the earlier kits, purchased about 4 years ago. Just a few questions .... Incase there has been any updates from the instruction manual:

Is CG still 160 mm back from the leading edge at the root of the wing panels ?

Control throw for elevator 20mm each way at tip ?

Any up or down thrust shins needed for the turbine mount (I will be using a JetCat P70) ?

Should I use any lubricant on the wheel brake pads ?

Thanks very much !

Bob

Is CG still 160 mm back from the leading edge at the root of the wing panels ?

Control throw for elevator 20mm each way at tip ?

Any up or down thrust shins needed for the turbine mount (I will be using a JetCat P70) ?

Should I use any lubricant on the wheel brake pads ?

Thanks very much !

Bob

#2360

Thread Starter

Bob

With 1/4 tank of fuel make the balance 170mm

20mm is ok for people who like powerful controls, you can go down to 18mm, though the elevator on an Xcalibur is not snappy sharp in control power. You need to fly it to set it how you like.

No additional shim should be needed with a big slugger of a turbine like the P-70. It’s only high efflux velocity units that sometime need a little more down thrust to remove the high speed exhaust gas from the tailplanes lower surface.

i would very lightly grease the wheel surface to reduce grabbing. The brakes are powerful.

With 1/4 tank of fuel make the balance 170mm

20mm is ok for people who like powerful controls, you can go down to 18mm, though the elevator on an Xcalibur is not snappy sharp in control power. You need to fly it to set it how you like.

No additional shim should be needed with a big slugger of a turbine like the P-70. It’s only high efflux velocity units that sometime need a little more down thrust to remove the high speed exhaust gas from the tailplanes lower surface.

i would very lightly grease the wheel surface to reduce grabbing. The brakes are powerful.

#2362

Join Date: Mar 2003

Location: BALLASALLA, CT, UNITED KINGDOM

Posts: 65

Likes: 0

Received 1 Like

on

1 Post

Hi I guess somewhere in the thread must be some setup suggestions for a novice jet pilot ? I have read for hours but not found them yet ! can someone point me to a post which may verify what I need or is the manual setup sufficient to start ?

Many thanks,

Paul.

Many thanks,

Paul.

#2363

Thread Starter

It’s so difficult to give figures not knowing a pilot, will you have someone you know test fly it? If they know you they can discuss your likes.

Xcalibur is sharper on elevator than aileron, so little more expo on elevator than aileron. Balance 170mm with a little fuel.

1mm down elevator with takeoff flap and 3mm with landing flap. As much Flap as you can get ( 80 degrees)

that will I’ll get you close

Xcalibur is sharper on elevator than aileron, so little more expo on elevator than aileron. Balance 170mm with a little fuel.

1mm down elevator with takeoff flap and 3mm with landing flap. As much Flap as you can get ( 80 degrees)

that will I’ll get you close

#2365

Join Date: Mar 2003

Location: BALLASALLA, CT, UNITED KINGDOM

Posts: 65

Likes: 0

Received 1 Like

on

1 Post

Itís so difficult to give figures not knowing a pilot, will you have someone you know test fly it? If they know you they can discuss your likes.

Xcalibur is sharper on elevator than aileron, so little more expo on elevator than aileron. Balance 170mm with a little fuel.

1mm down elevator with takeoff flap and 3mm with landing flap. As much Flap as you can get ( 80 degrees)

that will Iíll get you close

Xcalibur is sharper on elevator than aileron, so little more expo on elevator than aileron. Balance 170mm with a little fuel.

1mm down elevator with takeoff flap and 3mm with landing flap. As much Flap as you can get ( 80 degrees)

that will Iíll get you close

Cheers.

#2367

Here in the US we use Biobor EF anti-microbial additive to take care of just this sort of thing. My turbine colleagues highly recommend it. You probably already figured this out since I am responding to a late 2016 post. But I thought it might be worth the post. There is a product for Kerosene and one for diesel.

https://www.biobor.com/fuel-additive...uel-additives/

This stuff is extremely concentrated. A one pint U.S. bottle treats 640 US gallons.

https://www.biobor.com/fuel-additive...uel-additives/

This stuff is extremely concentrated. A one pint U.S. bottle treats 640 US gallons.

#2368

Join Date: Mar 2003

Location: BALLASALLA, CT, UNITED KINGDOM

Posts: 65

Likes: 0

Received 1 Like

on

1 Post

I have been unable to fly my jet for the past three months due to other matters, but this morning decided to prep it for flight again, it has only had one flight I should add. It was stored with the retracts up and some pressure in the system about 50 psi. The retracts would not come down either by manually pressing the buttons on the valve or from the Tx. After pressurising them back to 110psi they came down but worked intermittently for a while until they obviously freed off and now seem back to normal. Silly question time, is there a best way to preserve the system when not in use ? and is there anything to be used in terms of cylinder lubrication if they are laid up for some time? advice appreciated, thanks.

Paul.

Paul.

#2369

Thread Starter

Paul

Every flying session( first fill only), I put 2 drops (literally that) of Silicon buggy shock oil into the filler valve and then pressurise, this works through the system and reduces the moisture issue. Been doing this for 20 years and all my air retracts continue to hold air! Between 20 and 30WT

Dave

Every flying session( first fill only), I put 2 drops (literally that) of Silicon buggy shock oil into the filler valve and then pressurise, this works through the system and reduces the moisture issue. Been doing this for 20 years and all my air retracts continue to hold air! Between 20 and 30WT

Dave

Last edited by Dave Wilshere; 11-26-2019 at 08:39 AM.

#2370

Join Date: Mar 2003

Location: BALLASALLA, CT, UNITED KINGDOM

Posts: 65

Likes: 0

Received 1 Like

on

1 Post

Paul

Every flying session( first fill only), I put 2 drops (literally that) of Silicon buggy shock oil into the filler valve and then pressurise, this works through the system and reduces the moisture issue. Been doing this for 20 years and all my air retracts continue to hold air! Between 20 and 30WT

Dave

Every flying session( first fill only), I put 2 drops (literally that) of Silicon buggy shock oil into the filler valve and then pressurise, this works through the system and reduces the moisture issue. Been doing this for 20 years and all my air retracts continue to hold air! Between 20 and 30WT

Dave

Paul.

#2371

Junior Member

Join Date: Feb 2019

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Hi guys,

Need a bit of advice please.

Excalibur model.. KT 85g2

fuel line from CAT air trap to fuel pump issue maybe.

the fitting ID on the CAT is large.. ( like huge)

The fitting on the pump is only 2.5mm ID.

I will therefore need to reduce the fuel line.

I have read that very good article from a few years back on air traps and issues around possible cavitation.

my questions is..

Should the reducer be at the CAT end or the pump input end of the line.

my inclination would be to have it at the pump end ??

to make matters more confusing as I look at all the pictures on the forum I see reducers at both ends.

just dont want to build in a problem from the very start.

many thanks for any information.

Ray

NZ

Need a bit of advice please.

Excalibur model.. KT 85g2

fuel line from CAT air trap to fuel pump issue maybe.

the fitting ID on the CAT is large.. ( like huge)

The fitting on the pump is only 2.5mm ID.

I will therefore need to reduce the fuel line.

I have read that very good article from a few years back on air traps and issues around possible cavitation.

my questions is..

Should the reducer be at the CAT end or the pump input end of the line.

my inclination would be to have it at the pump end ??

to make matters more confusing as I look at all the pictures on the forum I see reducers at both ends.

just dont want to build in a problem from the very start.

many thanks for any information.

Ray

NZ

#2373

My Feedback: (53)

Hi guys,

Need a bit of advice please.

Excalibur model.. KT 85g2

fuel line from CAT air trap to fuel pump issue maybe.

the fitting ID on the CAT is large.. ( like huge)

The fitting on the pump is only 2.5mm ID.

I will therefore need to reduce the fuel line.

I have read that very good article from a few years back on air traps and issues around possible cavitation.

my questions is..

Should the reducer be at the CAT end or the pump input end of the line.

my inclination would be to have it at the pump end ??

to make matters more confusing as I look at all the pictures on the forum I see reducers at both ends.

just dont want to build in a problem from the very start.

many thanks for any information.

Ray

NZ

Need a bit of advice please.

Excalibur model.. KT 85g2

fuel line from CAT air trap to fuel pump issue maybe.

the fitting ID on the CAT is large.. ( like huge)

The fitting on the pump is only 2.5mm ID.

I will therefore need to reduce the fuel line.

I have read that very good article from a few years back on air traps and issues around possible cavitation.

my questions is..

Should the reducer be at the CAT end or the pump input end of the line.

my inclination would be to have it at the pump end ??

to make matters more confusing as I look at all the pictures on the forum I see reducers at both ends.

just dont want to build in a problem from the very start.

many thanks for any information.

Ray

NZ

#2374

Hi guys,

Need a bit of advice please.

Excalibur model.. KT 85g2

fuel line from CAT air trap to fuel pump issue maybe.

the fitting ID on the CAT is large.. ( like huge)

The fitting on the pump is only 2.5mm ID.

I will therefore need to reduce the fuel line.

I have read that very good article from a few years back on air traps and issues around possible cavitation.

my questions is..

Should the reducer be at the CAT end or the pump input end of the line.

my inclination would be to have it at the pump end ??

to make matters more confusing as I look at all the pictures on the forum I see reducers at both ends.

just dont want to build in a problem from the very start.

many thanks for any information.

Ray

NZ

Need a bit of advice please.

Excalibur model.. KT 85g2

fuel line from CAT air trap to fuel pump issue maybe.

the fitting ID on the CAT is large.. ( like huge)

The fitting on the pump is only 2.5mm ID.

I will therefore need to reduce the fuel line.

I have read that very good article from a few years back on air traps and issues around possible cavitation.

my questions is..

Should the reducer be at the CAT end or the pump input end of the line.

my inclination would be to have it at the pump end ??

to make matters more confusing as I look at all the pictures on the forum I see reducers at both ends.

just dont want to build in a problem from the very start.

many thanks for any information.

Ray

NZ

#2375

Junior Member

Join Date: Feb 2019

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Thanks guys for the information.

some good ideas there..

Thats a neat idea Dansy using a sleeve.... never thought of that.. thanks.

The Festo reducer looks tidy as well.

Dave, thanks for info.. you have confirmed what I was thinking.

cheers

Ray

some good ideas there..

Thats a neat idea Dansy using a sleeve.... never thought of that.. thanks.

The Festo reducer looks tidy as well.

Dave, thanks for info.. you have confirmed what I was thinking.

cheers

Ray