Xicoy - LG15 Gyro Controlled Brakes

#502

this thread is invaluable..holy smokes..thank you guys.

I just purchased an elan with JP gear. I have had 3 sets of electrons, so I got an LGC15 since they are sameish.. Im certainly not crazy about the JP gear, but the action is pretty smooth.

I was wondering about suggestions for settings now that alot of time has gone by since this thread was active.. right now Im just installing but I have them set to 1 amp for lack of anything better on a 2 cell lipo..and using 1/10th pulse..

I have a Cortex pro on the Nosewheel channel in EX mode, so it makes the jet go straight largely as it does others, so I didn't plan to use the gyro in the LGC.. but the smooth braking is what Im after.

Are you guys still taking out the bridge magnets? or taking 2 of 3, shimming? are you putting tubing in the struts, or shims too? guessing this jet will come in around the same weightas a flash.. I used the same gear on both back when.

This feels like dejavu all over again.. thx..goose. Im helping a buddy with a build too, so we are doing the elans together, he also has the LGC..

I love the electrons.. they are solid snd straight every time. hope I can get these brakes to that point.

I just purchased an elan with JP gear. I have had 3 sets of electrons, so I got an LGC15 since they are sameish.. Im certainly not crazy about the JP gear, but the action is pretty smooth.

I was wondering about suggestions for settings now that alot of time has gone by since this thread was active.. right now Im just installing but I have them set to 1 amp for lack of anything better on a 2 cell lipo..and using 1/10th pulse..

I have a Cortex pro on the Nosewheel channel in EX mode, so it makes the jet go straight largely as it does others, so I didn't plan to use the gyro in the LGC.. but the smooth braking is what Im after.

Are you guys still taking out the bridge magnets? or taking 2 of 3, shimming? are you putting tubing in the struts, or shims too? guessing this jet will come in around the same weightas a flash.. I used the same gear on both back when.

This feels like dejavu all over again.. thx..goose. Im helping a buddy with a build too, so we are doing the elans together, he also has the LGC..

I love the electrons.. they are solid snd straight every time. hope I can get these brakes to that point.

Last edited by gooseF22; 09-07-2022 at 05:26 PM.

The following users liked this post:

Desertlakesflying (11-11-2022)

#503

Thread Starter

I have two jets with JP retracts, both are T1 Minis. I'm running the JP wheels/brakes on one of them, and I'm running Electron Wheel/Brakes on the other. I removed all of the magnets from the JP Wheel/brakes. Both jets stop straight, even with hard braking. If I remember correctly my cutoff amperage is set to .7 Amps, I'm also using a 2S LiPo. I would start low and work your way up so you don't burn out the motors. Don't remember where I have brake pulse set, but I am using it as I do find it helpful in not locking up the wheels. For comparison to your jets, both of these jets weight about 20 lbs. Regards, Tom.

#504

Four years later this helped me.

The following 2 users liked this post by demolish:

Desertlakesflying (11-11-2022),

gooseF22 (08-01-2023)

#505

About removing the magnets in the JP wheels:

I removed mine because it was taking a lot of power to get the disks off the magnets. Then once they separated, the brakes would lock up on my Ultraflash. The heavier the plane, the less effect the magnets have on braking. This snapping off the magnets would cause a skid and my light plane would dance around and the stop would take a long rollout because I had to cycle the brakes on and off, etc. Once I took the magnets out of the wheels, the brakes stopped locking up. With the magnets out and an LGC15 the Ultraflash would stop on a dime with no dancing around, etc. I also took the magnets out on the T1. However, ...

After a couple hundred flights on each of those planes, both of these planes eventually wore the soft coating off the brake magnets and wound up having a metal-to-metal contact between the brake magnet and the disk. The disk's surfaces were severely scored. So, I ordered what I thought were replacement tire/wheel/brake assemblies from Hobby-China/JP. The new assemblies did NOT have disks. They have several magnets mounted inside the hub that do not make contact with the rotor. I had to bump up the max power a bit to get them to work the same. But they worked well. I ended up using these new style brakes on several of my planes.

I removed mine because it was taking a lot of power to get the disks off the magnets. Then once they separated, the brakes would lock up on my Ultraflash. The heavier the plane, the less effect the magnets have on braking. This snapping off the magnets would cause a skid and my light plane would dance around and the stop would take a long rollout because I had to cycle the brakes on and off, etc. Once I took the magnets out of the wheels, the brakes stopped locking up. With the magnets out and an LGC15 the Ultraflash would stop on a dime with no dancing around, etc. I also took the magnets out on the T1. However, ...

After a couple hundred flights on each of those planes, both of these planes eventually wore the soft coating off the brake magnets and wound up having a metal-to-metal contact between the brake magnet and the disk. The disk's surfaces were severely scored. So, I ordered what I thought were replacement tire/wheel/brake assemblies from Hobby-China/JP. The new assemblies did NOT have disks. They have several magnets mounted inside the hub that do not make contact with the rotor. I had to bump up the max power a bit to get them to work the same. But they worked well. I ended up using these new style brakes on several of my planes.

Last edited by Len Todd; 11-11-2022 at 06:51 AM.

#506

About removing the magnets in the JP wheels:

I removed mine because it was taking a lot of power to get the disks off the magnets. Then once they separated, the brakes would lock up on my Ultraflash. The heavier the plane, the less effect the magnets have on braking. This snapping off the magnets would cause a skid and my light plane would dance around and the stop would take a long rollout because I had to cycle the brakes on and off, etc. Once I took the magnets out of the wheels, the brakes stopped locking up. With the magnets out and an LGC15 the Ultraflash would stop on a dime with no dancing around, etc. I also took the magnets out on the T1. However, ...

After a couple hundred flights on each of those planes, both of these planes eventually wore the soft coating off the brake magnets and wound up having a metal-to-metal contact between the brake magnet and the disk. The disk's surfaces were severely scored. So, I ordered what I thought were replacement tire/wheel/brake assemblies from Hobby-China/JP. The new assemblies did NOT have disks. They have several magnets mounted inside the hub that do not make contact with the rotor. I had to bump up the max power a bit to get them to work the same. But they worked well. I ended up using these new style brakes on several of my planes.

I removed mine because it was taking a lot of power to get the disks off the magnets. Then once they separated, the brakes would lock up on my Ultraflash. The heavier the plane, the less effect the magnets have on braking. This snapping off the magnets would cause a skid and my light plane would dance around and the stop would take a long rollout because I had to cycle the brakes on and off, etc. Once I took the magnets out of the wheels, the brakes stopped locking up. With the magnets out and an LGC15 the Ultraflash would stop on a dime with no dancing around, etc. I also took the magnets out on the T1. However, ...

After a couple hundred flights on each of those planes, both of these planes eventually wore the soft coating off the brake magnets and wound up having a metal-to-metal contact between the brake magnet and the disk. The disk's surfaces were severely scored. So, I ordered what I thought were replacement tire/wheel/brake assemblies from Hobby-China/JP. The new assemblies did NOT have disks. They have several magnets mounted inside the hub that do not make contact with the rotor. I had to bump up the max power a bit to get them to work the same. But they worked well. I ended up using these new style brakes on several of my planes.

thanks,

Tone

The following users liked this post:

Tip22v (11-16-2022)

The following users liked this post:

mongo (11-19-2022)

#509

JP Hobby 2pcs Electric Brake 82.5MM (3" 1/4) Wheels and Controller (8mm axle) for Turbo version model JP-EBW-82 for rc models Sale | wholesale - Hobby-China Co.,LTd.

They have been around for a while. I picked up two sets late last year and have one that is installed. I gave away the Brake Controller that comes with the set. If one has JP gear, it might just pay one to look over their website. In the past I have contacted them for parts they do not list on the website. While they are sometimes slow to respond to email, I did get the parts that I was looking for. But I paid more for shipping than the coast of the parts, etc.

They have been around for a while. I picked up two sets late last year and have one that is installed. I gave away the Brake Controller that comes with the set. If one has JP gear, it might just pay one to look over their website. In the past I have contacted them for parts they do not list on the website. While they are sometimes slow to respond to email, I did get the parts that I was looking for. But I paid more for shipping than the coast of the parts, etc.

#510

The LGC15 Manual is a bit light on explaining the difference between the "Proportional" and the "Heading Hold" brake setting. I have tested both. Both have worked well for me depending on the length and width of the runways. Depending on the quality of the landing approach, heading hold can work well on long wide runways. On these types of runways, if necessary to correct the direction of the plane after the brakes have been applied, one can disengage the brakes, adjust the direction of travel and reapply brakes. On short and or narrow runways where rollouts need to be short and direction is more critical, I have found the Proportional setting to be more suitable. With a Proportional brake setting, rollouts, when direction changes were needed, were much shorter.

So, ... I asked Gaspar for his explanation re. the difference between the two Brake Setting. Below is his answer:"In proportional mode the gyro reacts to changes in heading, so, for example, when the heading changes to the left, the right brake has more power than left to counteract the change of heading but return to neutral steering when the heading change stops. Meaning, if the model is pointing to the north, and you rotate to east, the brakes will try to counteract this rotation by applying more brake force to left brake. But once the plane sits steady pointing east, the brakes will return to normal.

In heading lock mode, the gyro reacts to changes in nose heading position, when you apply the brake, you "define" the direction you want the plane to run. If, in same case as above, if when braking in heading hold mode you move the nose to the left, right brake will be applied to return to the direction that the plane was pointing when you applied the brake. Meaning, if the model is pointing to the north, and you rotate to east, the brakes will try to counteract this rotation by applying more brake force to left brake until the plane is returned back to the North position it was when you applied brakes.

Hope is clear. You can see the behavior easily on the ground by moving the nose left/right in both modes, while watching the screen to see the power of brake force applied in each wheel.

Gaspar"

Recently someone asked me about this. I hope the above discussion and Gaspar's explanation clears this particular LGC15 setting up. I know we have discussed it before. But I thought it would be good to post the OEM's explanation.

So, ... I asked Gaspar for his explanation re. the difference between the two Brake Setting. Below is his answer:"In proportional mode the gyro reacts to changes in heading, so, for example, when the heading changes to the left, the right brake has more power than left to counteract the change of heading but return to neutral steering when the heading change stops. Meaning, if the model is pointing to the north, and you rotate to east, the brakes will try to counteract this rotation by applying more brake force to left brake. But once the plane sits steady pointing east, the brakes will return to normal.

In heading lock mode, the gyro reacts to changes in nose heading position, when you apply the brake, you "define" the direction you want the plane to run. If, in same case as above, if when braking in heading hold mode you move the nose to the left, right brake will be applied to return to the direction that the plane was pointing when you applied the brake. Meaning, if the model is pointing to the north, and you rotate to east, the brakes will try to counteract this rotation by applying more brake force to left brake until the plane is returned back to the North position it was when you applied brakes.

Hope is clear. You can see the behavior easily on the ground by moving the nose left/right in both modes, while watching the screen to see the power of brake force applied in each wheel.

Gaspar"

Recently someone asked me about this. I hope the above discussion and Gaspar's explanation clears this particular LGC15 setting up. I know we have discussed it before. But I thought it would be good to post the OEM's explanation.

Last edited by Len Todd; 11-24-2022 at 08:26 AM.

#511

I installed a new LG-15 in a Pilot RC F-16. I have had 5 flights on it so far and twice the brakes failed to engage completely. The first time, after retrieving the jet, the brakes did not work, I had to turn it of/on and then the brake engaged. The second time, after retrieving the jet, the brakes were working without having to reset the controller.

Doors and retracts work fine every time. I am using a dedicated 2S Lipo, 900 mah 25C. Any help is much appreciated.

Doors and retracts work fine every time. I am using a dedicated 2S Lipo, 900 mah 25C. Any help is much appreciated.

#512

Senior Member

I installed a new LG-15 in a Pilot RC F-16. I have had 5 flights on it so far and twice the brakes failed to engage completely. The first time, after retrieving the jet, the brakes did not work, I had to turn it of/on and then the brake engaged. The second time, after retrieving the jet, the brakes were working without having to reset the controller.

Doors and retracts work fine every time. I am using a dedicated 2S Lipo, 900 mah 25C. Any help is much appreciated.

Doors and retracts work fine every time. I am using a dedicated 2S Lipo, 900 mah 25C. Any help is much appreciated.

#513

I typically put the plane on the stand and test the brakes by hand many times before taking the plane to the field. That being said, ...

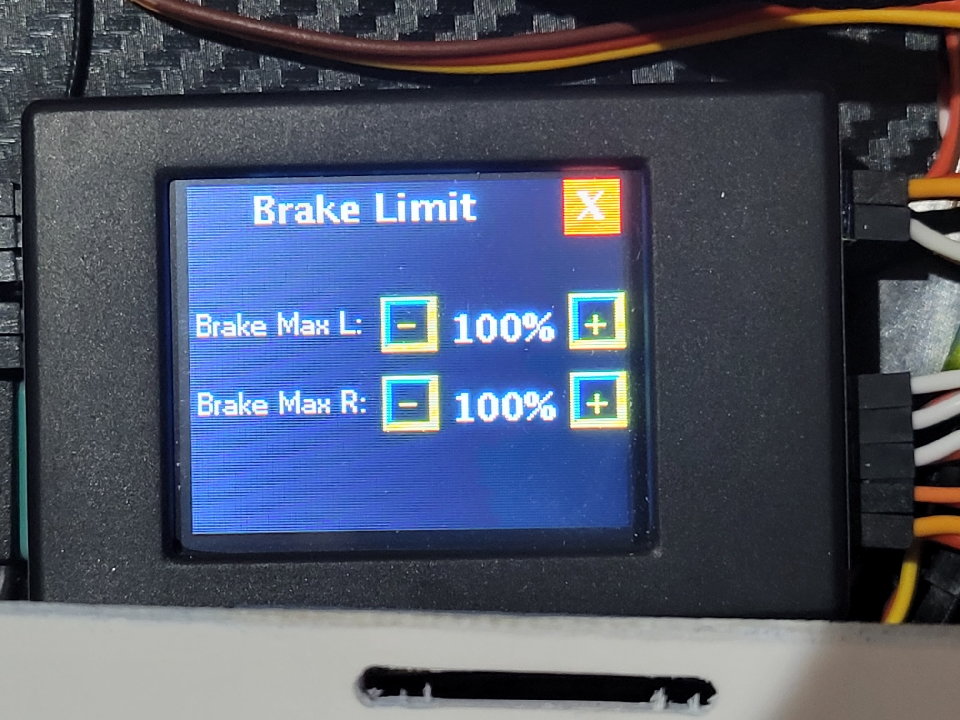

When you apply the brakes, do the Brake LED sequences on the LGC15 show that the power is being applied to at least 80%? When the LGC15 shows the power being applied, are the brakes actually working? What are your LGC15 Brake Limit settings? That is an additional sub-menu from the Brake setting menu. Some folks miss that. I usually start out around 80% and adjust from there.

If you are using older JP Gear, there were permanent magnets in the hub that held the disks back from the electro-magnets and it took a lot of brake power to get the disks off the permanent magnets and then the brakes would lock up on lighter planes. If your Brake Limit level was not high enough, the brakes did not work consistently. JP also has a set of brakes/ style that have no disks. They work more reliably but they may not work well enough on very heavy planes. They do work well on my 34# plane though.

If the LGC15 shows on the LEDs that power is being applied and the brakes are not reliably working, then the issue is in either the wiring down to the brakes or the brakes themselves! Did you clean the brakes when they were installed? If you did, did they go back together correctly? One does NOT use lube on electric brakes. Could there be an intermittent wiring issue?

What type of gear are you using? What are the current Brake power level settings? If there is a metal disk involved, it can become magnetized itself and initially work intermittently. Once you work the brakes a couple times, the effect of the magnetized disk is minimized. The effect is more noticeable on lighter planes. But that is NOT a controller issue. The resulting locking up can be minimized by use of the ant-lock and individual power level adjustments.

Below is a list of the settings that I initially start out with for my typical builds. Once everything is working correctly on the bench, I go to the field and run a bunch of taxi tests to fine tune the Brake, Steering (e.g. Gyro) settings.

When you apply the brakes, do the Brake LED sequences on the LGC15 show that the power is being applied to at least 80%? When the LGC15 shows the power being applied, are the brakes actually working? What are your LGC15 Brake Limit settings? That is an additional sub-menu from the Brake setting menu. Some folks miss that. I usually start out around 80% and adjust from there.

If you are using older JP Gear, there were permanent magnets in the hub that held the disks back from the electro-magnets and it took a lot of brake power to get the disks off the permanent magnets and then the brakes would lock up on lighter planes. If your Brake Limit level was not high enough, the brakes did not work consistently. JP also has a set of brakes/ style that have no disks. They work more reliably but they may not work well enough on very heavy planes. They do work well on my 34# plane though.

If the LGC15 shows on the LEDs that power is being applied and the brakes are not reliably working, then the issue is in either the wiring down to the brakes or the brakes themselves! Did you clean the brakes when they were installed? If you did, did they go back together correctly? One does NOT use lube on electric brakes. Could there be an intermittent wiring issue?

What type of gear are you using? What are the current Brake power level settings? If there is a metal disk involved, it can become magnetized itself and initially work intermittently. Once you work the brakes a couple times, the effect of the magnetized disk is minimized. The effect is more noticeable on lighter planes. But that is NOT a controller issue. The resulting locking up can be minimized by use of the ant-lock and individual power level adjustments.

Below is a list of the settings that I initially start out with for my typical builds. Once everything is working correctly on the bench, I go to the field and run a bunch of taxi tests to fine tune the Brake, Steering (e.g. Gyro) settings.

Last edited by Len Todd; 12-28-2022 at 10:34 AM.

#514

I typically put the plane on the stand and test the brakes by hand many times before taking the plane to the field. That being said, ...

When you apply the brakes, do the Brake LED sequences on the LGC15 show that the power is being applied to at least 80%? When the LGC15 shows the power being applied, are the brakes actually working? What are your LGC15 Brake Limit settings? That is an additional sub-menu from the Brake setting menu. Some folks miss that. I usually start out around 80% and adjust from there.

If you are using older JP Gear, there were permanent magnets in the hub that held the disks back from the electro-magnets and it took a lot of brake power to get the disks off the permanent magnets and then the brakes would lock up on lighter planes. If your Brake Limit level was not high enough, the brakes did not work consistently. JP also has a set of brakes/ style that have no disks. They work more reliably but they may not work well enough on very heavy planes. They do work well on my 34# plane though.

If the LGC15 shows on the LEDs that power is being applied and the brakes are not reliably working, then the issue is in either the wiring down to the brakes or the brakes themselves! Did you clean the brakes when they were installed? If you did, did they go back together correctly? One does NOT use lube on electric brakes. Could there be an intermittent wiring issue?

What type of gear are you using? What are the current Brake power level settings? If there is a metal disk involved, it can become magnetized itself and initially work intermittently. Once you work the brakes a couple times, the effect of the magnetized disk is minimized. The effect is more noticeable on lighter planes. But that is NOT a controller issue. The resulting locking up can be minimized by use of the ant-lock and individual power level adjustments.

Below is a list of the settings that I initially start out with for my typical builds. Once everything is working correctly on the bench, I go to the field and run a bunch of taxi tests to fine tune the Brake, Steering (e.g. Gyro) settings.

When you apply the brakes, do the Brake LED sequences on the LGC15 show that the power is being applied to at least 80%? When the LGC15 shows the power being applied, are the brakes actually working? What are your LGC15 Brake Limit settings? That is an additional sub-menu from the Brake setting menu. Some folks miss that. I usually start out around 80% and adjust from there.

If you are using older JP Gear, there were permanent magnets in the hub that held the disks back from the electro-magnets and it took a lot of brake power to get the disks off the permanent magnets and then the brakes would lock up on lighter planes. If your Brake Limit level was not high enough, the brakes did not work consistently. JP also has a set of brakes/ style that have no disks. They work more reliably but they may not work well enough on very heavy planes. They do work well on my 34# plane though.

If the LGC15 shows on the LEDs that power is being applied and the brakes are not reliably working, then the issue is in either the wiring down to the brakes or the brakes themselves! Did you clean the brakes when they were installed? If you did, did they go back together correctly? One does NOT use lube on electric brakes. Could there be an intermittent wiring issue?

What type of gear are you using? What are the current Brake power level settings? If there is a metal disk involved, it can become magnetized itself and initially work intermittently. Once you work the brakes a couple times, the effect of the magnetized disk is minimized. The effect is more noticeable on lighter planes. But that is NOT a controller issue. The resulting locking up can be minimized by use of the ant-lock and individual power level adjustments.

Below is a list of the settings that I initially start out with for my typical builds. Once everything is working correctly on the bench, I go to the field and run a bunch of taxi tests to fine tune the Brake, Steering (e.g. Gyro) settings.

The brake limits are set at 100%, please see screen shots. Should I lower them to 80%?

The Pilot RC F-16 I have is a brand new model, I think Pilot-RC uses rebranded JP retracts because the controllers that came with the jet look identical to JP so do the retracts. On the wheel, it says JP. I have not disassembled the brakes, they do work 100% of the time on the ground, the LED shows brake being applied and the brakes engage.

Last edited by N4S; 12-28-2022 at 04:14 PM.

#516

A brake's electro-magnet could fail. However, it is unlikely that both would fail at the same time. You did NOT mention if the when the brakes work, do both sides work (i.e. Does the plane stop w/o any negative directional impact on the plane.)? If the plane does not veer off-course when the brakes are applied, then I doubt you have a mechanical brake failure. But if these are used and worn brakes, then both could be mechanically or electrically failing. Again, are these new or used gear?

They look like JP gear. But the axle does not have the retaining bolt in the end of the axle nor the hub cap over the axle. This is a third design, which is new to me. I can't tell for sure if you have the metal disk inside of the hub. If there is a metal disk inside the brake, the spacers on the axle are critical. Is this new gear or used gear? If it is used or old gear, I would start by disassembling a brake and ensure it is mechanically correct. If the gear is used, the space between the electro-magnets and the hub can get too wide and the disks can disengage from the counter-rotation pins. If that happens, the brakes sometimes do not work. If that is happening, there are typically marks on the disk on the side of the disk opposite of the electro-magnets. Of course, this assumes there is even a disk inside the brakes and that they are NOT new.

Again, I would put the plane on the stand and apply the brakes a couple dozen times to make sure the electro-magnets are energizing every time. If they are consistently energizing, then you have a mechanical issue inside the brake itself. If they are NOT consistently energizing, then you may have an electrical issue. Test the wiring and connections. Given that you occasionally have brakes at the field, I assume you have the PINOUT on the brake harness with the pins in JR connector's sockets 1 and 3 like the gear. Right? If the connections are all good and there is a voltage applied at the LGC15's Brake output when the brakes should be on, then I would disassemble the brake and figure out what is going on in the brake itself. If the brake is all good or they are new gear, then I might question the LGC15. I have one that was crashed, and the steering was glitching every now and then. But that was a severe crash. Usually if there is an issue that I have heard about or experienced, it is either the programming or the mechanics in the brake itself. I have had 6 of these and have programmed many others. They typically are solid units.

What transmitter are you using and what % of travel is your transmitter inputting into the LCG15? When you start checking the wiring, don't forget the wire between the receiver and the LGC. When I start electrical troubleshooting, I typically start at the receiver output with a PWM meter to ensure the transmitter/receiver combination is outputting the proper signal to the downstream device. Then I move downstream. I would then check the Voltage output of the LCG15 to the Brake with a voltmeter. If you consistently have voltage showing up at the LGC's Brake output when the brakes are applied at the transmitter, then you know you either have a brake wire/connection issue or a mechanical problem in the brakes. Again, if there is a disk inside the brake, the space between the carrying hub and the electro-magnet is critical. Those tiny spacers on the axle make a big difference and they have to be right. They do wear. But new gear has never presented a problem for me.

I would also bump up the anti-lock ratio to at least 1/5 or 1/10 and try the brakes again on the bench. I would also program in some brake steering % (e.g. at least 10%) to start with. Use the Brake Gyro to ensure the steering correction is in the correct direction (i.e. + or - ). On yours, the current settings are not taking advantage of the LGC15's best features.

They look like JP gear. But the axle does not have the retaining bolt in the end of the axle nor the hub cap over the axle. This is a third design, which is new to me. I can't tell for sure if you have the metal disk inside of the hub. If there is a metal disk inside the brake, the spacers on the axle are critical. Is this new gear or used gear? If it is used or old gear, I would start by disassembling a brake and ensure it is mechanically correct. If the gear is used, the space between the electro-magnets and the hub can get too wide and the disks can disengage from the counter-rotation pins. If that happens, the brakes sometimes do not work. If that is happening, there are typically marks on the disk on the side of the disk opposite of the electro-magnets. Of course, this assumes there is even a disk inside the brakes and that they are NOT new.

Again, I would put the plane on the stand and apply the brakes a couple dozen times to make sure the electro-magnets are energizing every time. If they are consistently energizing, then you have a mechanical issue inside the brake itself. If they are NOT consistently energizing, then you may have an electrical issue. Test the wiring and connections. Given that you occasionally have brakes at the field, I assume you have the PINOUT on the brake harness with the pins in JR connector's sockets 1 and 3 like the gear. Right? If the connections are all good and there is a voltage applied at the LGC15's Brake output when the brakes should be on, then I would disassemble the brake and figure out what is going on in the brake itself. If the brake is all good or they are new gear, then I might question the LGC15. I have one that was crashed, and the steering was glitching every now and then. But that was a severe crash. Usually if there is an issue that I have heard about or experienced, it is either the programming or the mechanics in the brake itself. I have had 6 of these and have programmed many others. They typically are solid units.

What transmitter are you using and what % of travel is your transmitter inputting into the LCG15? When you start checking the wiring, don't forget the wire between the receiver and the LGC. When I start electrical troubleshooting, I typically start at the receiver output with a PWM meter to ensure the transmitter/receiver combination is outputting the proper signal to the downstream device. Then I move downstream. I would then check the Voltage output of the LCG15 to the Brake with a voltmeter. If you consistently have voltage showing up at the LGC's Brake output when the brakes are applied at the transmitter, then you know you either have a brake wire/connection issue or a mechanical problem in the brakes. Again, if there is a disk inside the brake, the space between the carrying hub and the electro-magnet is critical. Those tiny spacers on the axle make a big difference and they have to be right. They do wear. But new gear has never presented a problem for me.

I would also bump up the anti-lock ratio to at least 1/5 or 1/10 and try the brakes again on the bench. I would also program in some brake steering % (e.g. at least 10%) to start with. Use the Brake Gyro to ensure the steering correction is in the correct direction (i.e. + or - ). On yours, the current settings are not taking advantage of the LGC15's best features.

#517

Electric brake systems are complex. However, overall, they are by far superior to air systems. I have had several of both types. You don't have to grease electric brakes, you do not have to worry about air leaks causing your gear to fail, causing a crash, and electrics are extremely reliable. The LGC15 even gives you brake steering and ABS, which allows the adjustments necessary to stop brake lockups that result in brake dancing and/or excessive tire wear or even worse, wheel/tire separation! The LGC15 also allows the controller to keep the plane on course even when the brakes do not have even contact with the runway or the brake mechanics do not apply braking evenly! When you have a lighter plane, the LGC15 allows you to just push up the slider fully and the controller stops the plane w/o dancing around and in the shortest possible distance, CONSISTENTLY. Tires last longer and they do not get flat spots. The landing is completely controlled w/o any input other than just turning on the brakes, ...once.

However, electric brakes do take some understanding of the controller's programming and even the best controller cannot compensate for failing brakes of any kind (i.e. the brakes have to work too.) Once you understand the necessary programming, the LGC15 is a snap to setup. You can even use an SD card to swap programs between planes and then make just minor adjustments to accommodate the specific plane's peculiarities.

I'll never go back to air powered gear and the LGC15 is the answer to making electric brakes work correctly!

However, electric brakes do take some understanding of the controller's programming and even the best controller cannot compensate for failing brakes of any kind (i.e. the brakes have to work too.) Once you understand the necessary programming, the LGC15 is a snap to setup. You can even use an SD card to swap programs between planes and then make just minor adjustments to accommodate the specific plane's peculiarities.

I'll never go back to air powered gear and the LGC15 is the answer to making electric brakes work correctly!

The following users liked this post:

Agrav8ed (12-29-2022)

#518

A brake's electro-magnet could fail. However, it is unlikely that both would fail at the same time. You did NOT mention if the when the brakes work, do both sides work (i.e. Does the plane stop w/o any negative directional impact on the plane.)? If the plane does not veer off-course when the brakes are applied, then I doubt you have a mechanical brake failure. But if these are used and worn brakes, then both could be mechanically or electrically failing. Again, are these new or used gear?

They look like JP gear. But the axle does not have the retaining bolt in the end of the axle nor the hub cap over the axle. This is a third design, which is new to me. I can't tell for sure if you have the metal disk inside of the hub. If there is a metal disk inside the brake, the spacers on the axle are critical. Is this new gear or used gear? If it is used or old gear, I would start by disassembling a brake and ensure it is mechanically correct. If the gear is used, the space between the electro-magnets and the hub can get too wide and the disks can disengage from the counter-rotation pins. If that happens, the brakes sometimes do not work. If that is happening, there are typically marks on the disk on the side of the disk opposite of the electro-magnets. Of course, this assumes there is even a disk inside the brakes and that they are NOT new.

Again, I would put the plane on the stand and apply the brakes a couple dozen times to make sure the electro-magnets are energizing every time. If they are consistently energizing, then you have a mechanical issue inside the brake itself. If they are NOT consistently energizing, then you may have an electrical issue. Test the wiring and connections. Given that you occasionally have brakes at the field, I assume you have the PINOUT on the brake harness with the pins in JR connector's sockets 1 and 3 like the gear. Right? If the connections are all good and there is a voltage applied at the LGC15's Brake output when the brakes should be on, then I would disassemble the brake and figure out what is going on in the brake itself. If the brake is all good or they are new gear, then I might question the LGC15. I have one that was crashed, and the steering was glitching every now and then. But that was a severe crash. Usually if there is an issue that I have heard about or experienced, it is either the programming or the mechanics in the brake itself. I have had 6 of these and have programmed many others. They typically are solid units.

What transmitter are you using and what % of travel is your transmitter inputting into the LCG15? When you start checking the wiring, don't forget the wire between the receiver and the LGC. When I start electrical troubleshooting, I typically start at the receiver output with a PWM meter to ensure the transmitter/receiver combination is outputting the proper signal to the downstream device. Then I move downstream. I would then check the Voltage output of the LCG15 to the Brake with a voltmeter. If you consistently have voltage showing up at the LGC's Brake output when the brakes are applied at the transmitter, then you know you either have a brake wire/connection issue or a mechanical problem in the brakes. Again, if there is a disk inside the brake, the space between the carrying hub and the electro-magnet is critical. Those tiny spacers on the axle make a big difference and they have to be right. They do wear. But new gear has never presented a problem for me.

I would also bump up the anti-lock ratio to at least 1/5 or 1/10 and try the brakes again on the bench. I would also program in some brake steering % (e.g. at least 10%) to start with. Use the Brake Gyro to ensure the steering correction is in the correct direction (i.e. + or - ). On yours, the current settings are not taking advantage of the LGC15's best features.

They look like JP gear. But the axle does not have the retaining bolt in the end of the axle nor the hub cap over the axle. This is a third design, which is new to me. I can't tell for sure if you have the metal disk inside of the hub. If there is a metal disk inside the brake, the spacers on the axle are critical. Is this new gear or used gear? If it is used or old gear, I would start by disassembling a brake and ensure it is mechanically correct. If the gear is used, the space between the electro-magnets and the hub can get too wide and the disks can disengage from the counter-rotation pins. If that happens, the brakes sometimes do not work. If that is happening, there are typically marks on the disk on the side of the disk opposite of the electro-magnets. Of course, this assumes there is even a disk inside the brakes and that they are NOT new.

Again, I would put the plane on the stand and apply the brakes a couple dozen times to make sure the electro-magnets are energizing every time. If they are consistently energizing, then you have a mechanical issue inside the brake itself. If they are NOT consistently energizing, then you may have an electrical issue. Test the wiring and connections. Given that you occasionally have brakes at the field, I assume you have the PINOUT on the brake harness with the pins in JR connector's sockets 1 and 3 like the gear. Right? If the connections are all good and there is a voltage applied at the LGC15's Brake output when the brakes should be on, then I would disassemble the brake and figure out what is going on in the brake itself. If the brake is all good or they are new gear, then I might question the LGC15. I have one that was crashed, and the steering was glitching every now and then. But that was a severe crash. Usually if there is an issue that I have heard about or experienced, it is either the programming or the mechanics in the brake itself. I have had 6 of these and have programmed many others. They typically are solid units.

What transmitter are you using and what % of travel is your transmitter inputting into the LCG15? When you start checking the wiring, don't forget the wire between the receiver and the LGC. When I start electrical troubleshooting, I typically start at the receiver output with a PWM meter to ensure the transmitter/receiver combination is outputting the proper signal to the downstream device. Then I move downstream. I would then check the Voltage output of the LCG15 to the Brake with a voltmeter. If you consistently have voltage showing up at the LGC's Brake output when the brakes are applied at the transmitter, then you know you either have a brake wire/connection issue or a mechanical problem in the brakes. Again, if there is a disk inside the brake, the space between the carrying hub and the electro-magnet is critical. Those tiny spacers on the axle make a big difference and they have to be right. They do wear. But new gear has never presented a problem for me.

I would also bump up the anti-lock ratio to at least 1/5 or 1/10 and try the brakes again on the bench. I would also program in some brake steering % (e.g. at least 10%) to start with. Use the Brake Gyro to ensure the steering correction is in the correct direction (i.e. + or - ). On yours, the current settings are not taking advantage of the LGC15's best features.

The retracts are brand new. The Pilot-RC F-16 was a PNP so all parts are brand new. I have tested the brakes on the stand more than 40 times and they work every time on both sides.

I want to say the the 2 instances that brakes did not work, neither side engaged as it would have slowed it down a little if one side had worked. We have a 600 Ft. paved runway, I touched down near the beginning of runway and it run almost 400 ft and eventually run into the grass. The other 3 times they worked well and stopped it in less than 80-100 FT. I do use the steering gyro function.

I am using an FrSky X20S transmitter. My brake in my TX was set -100 to 100, I just changed it to -100 to 120 when I saw your question. I remember I had an EA Viper and had to change the positive side to 120 to make it work, but the issue with Viper was consistent and not intermittent like the F-16.

What does bumping up the anti-lock ratio to 1/5 or 1/10 do?

I checked the wiring, and all look good. I wiggled the brake wires while brake was applied and didn't find a short. My next step is to change the RX and fly it as I am not sure what else to do.

Last edited by N4S; 12-29-2022 at 04:23 PM.

#519

If it worked OK 40 times on the bench since you had the issue, then I would say it is working. Maybe they brakes have the metal disks and there was some lube or preservative on there that got burned off after braking a couple times. ??

Before changing the Rxer, I would test its output with a PWM Meter a couple dozen times. I don't know anyone who uses that brand RF system on Jets, and I have never seen one of those show up at my jet events. So, I can't tell you why you would need more than 100% travel on the Txer. I do have a couple glider pilots who use that brand and have been flying very high with that brand TXer .Those pilots seem to like some of the apparently unique features. But with your LGC's Brake limits set at 100%, you should see some braking when the TXer outputs 100%.

Bumping up the anti-lock ratio increase the frequency of anti-locking cycle (i.e. works the cycle more frequently)

The other circuit to check would be the battery power to the LGC. But those brakes should work with even 6 volts let alone 2S LiPo. If the gear is deploying and retracting consistently, then you have adequate power to the LGC for braking.

I always seem to have a spare LGC15 around getting ready for the next build, etc. If I had this issue, at this point I would swap the LGC out and try the spare. If I had to, I could always jerk an LGC from one of the other planes for testing too. After fiddling around for a couple hours, I ended up swapping a previously crashed one out. You may want to look into swapping yours out or contacting Gaspar directly. It is hard troubleshooting w/o it being on the bench in front of me and working the problem from start to finish. I have given you all the related info I can think of. Please do let us know what you eventually find out. Good Luck!

Before changing the Rxer, I would test its output with a PWM Meter a couple dozen times. I don't know anyone who uses that brand RF system on Jets, and I have never seen one of those show up at my jet events. So, I can't tell you why you would need more than 100% travel on the Txer. I do have a couple glider pilots who use that brand and have been flying very high with that brand TXer .Those pilots seem to like some of the apparently unique features. But with your LGC's Brake limits set at 100%, you should see some braking when the TXer outputs 100%.

Bumping up the anti-lock ratio increase the frequency of anti-locking cycle (i.e. works the cycle more frequently)

The other circuit to check would be the battery power to the LGC. But those brakes should work with even 6 volts let alone 2S LiPo. If the gear is deploying and retracting consistently, then you have adequate power to the LGC for braking.

I always seem to have a spare LGC15 around getting ready for the next build, etc. If I had this issue, at this point I would swap the LGC out and try the spare. If I had to, I could always jerk an LGC from one of the other planes for testing too. After fiddling around for a couple hours, I ended up swapping a previously crashed one out. You may want to look into swapping yours out or contacting Gaspar directly. It is hard troubleshooting w/o it being on the bench in front of me and working the problem from start to finish. I have given you all the related info I can think of. Please do let us know what you eventually find out. Good Luck!

#520

I'm building an Aerofoam L-39 105mm EDF and there's a problem with the included gear sequencer. Banana Hobby has been very good about the issue and is sending an updated unit as soon as it's available. I'm thinking of replacing the AG63Pro steering gyro and gear/sequence units with the Xicoy LG-15. Gear controllers are new territory for me and I have a few questions.

1- For the steering in and out, the manual says you "can use a Y-lead from the rudder channel" (I don't have an extra Rx channel for a separate steering channel). My rudder signal goes from the Futaba Rx to the Demon Cortex gyro via S-BUS and then a lead comes out of the gyro to the rudder. If I Y the rudder lead between the gyro and rudder and send that signal to the LG-15 steering in, will that work, or will the two gyro's fight each other?

2- Does a mating MPX connector come with the unit to attach my power supply to?

3- I have an external BEC with 6 volts going to the Rx and 7.4 or 8.4 volts to the LG-15. Will this work okay?

Thank, Rich

1- For the steering in and out, the manual says you "can use a Y-lead from the rudder channel" (I don't have an extra Rx channel for a separate steering channel). My rudder signal goes from the Futaba Rx to the Demon Cortex gyro via S-BUS and then a lead comes out of the gyro to the rudder. If I Y the rudder lead between the gyro and rudder and send that signal to the LG-15 steering in, will that work, or will the two gyro's fight each other?

2- Does a mating MPX connector come with the unit to attach my power supply to?

3- I have an external BEC with 6 volts going to the Rx and 7.4 or 8.4 volts to the LG-15. Will this work okay?

Thank, Rich

#521

My Feedback: (1)

I am finishing up the AF L-39 too. Mine is turbine.

My gear controller worked but it always retracted the landing gear upon powering up. This is not ideal, I had a LG15 in my shop, and replaced the stock electronics with it, It works much better.

I use a bus connected Cortex Pro. I use port six for the front steering. So the Cortex is controlling steering. I think you can tell the Cortex to not stabilize a single port and then run the signal thru the brake gyro, if you didn't want the Cortex to do it. That is a way to avoid a wye cable.

My gear controller worked but it always retracted the landing gear upon powering up. This is not ideal, I had a LG15 in my shop, and replaced the stock electronics with it, It works much better.

I use a bus connected Cortex Pro. I use port six for the front steering. So the Cortex is controlling steering. I think you can tell the Cortex to not stabilize a single port and then run the signal thru the brake gyro, if you didn't want the Cortex to do it. That is a way to avoid a wye cable.

#522

I am finishing up the AF L-39 too. Mine is turbine.

My gear controller worked but it always retracted the landing gear upon powering up. This is not ideal, I had a LG15 in my shop, and replaced the stock electronics with it, It works much better.

I use a bus connected Cortex Pro. I use port six for the front steering. So the Cortex is controlling steering. I think you can tell the Cortex to not stabilize a single port and then run the signal thru the brake gyro, if you didn't want the Cortex to do it. That is a way to avoid a wye cable.

My gear controller worked but it always retracted the landing gear upon powering up. This is not ideal, I had a LG15 in my shop, and replaced the stock electronics with it, It works much better.

I use a bus connected Cortex Pro. I use port six for the front steering. So the Cortex is controlling steering. I think you can tell the Cortex to not stabilize a single port and then run the signal thru the brake gyro, if you didn't want the Cortex to do it. That is a way to avoid a wye cable.

That's good to hear that you're happy with the LG-15.

Last edited by RC Rich; 12-30-2022 at 07:02 PM.

#523

I'm building an Aerofoam L-39 105mm EDF and there's a problem with the included gear sequencer. Banana Hobby has been very good about the issue and is sending an updated unit as soon as it's available. I'm thinking of replacing the AG63Pro steering gyro and gear/sequence units with the Xicoy LG-15. Gear controllers are new territory for me and I have a few questions.

1- For the steering in and out, the manual says you "can use a Y-lead from the rudder channel" (I don't have an extra Rx channel for a separate steering channel). My rudder signal goes from the Futaba Rx to the Demon Cortex gyro via S-BUS and then a lead comes out of the gyro to the rudder. If I Y the rudder lead between the gyro and rudder and send that signal to the LG-15 steering in, will that work, or will the two gyro's fight each other?

2- Does a mating MPX connector come with the unit to attach my power supply to?

3- I have an external BEC with 6 volts going to the Rx and 7.4 or 8.4 volts to the LG-15. Will this work okay?

Thank, Rich

1- For the steering in and out, the manual says you "can use a Y-lead from the rudder channel" (I don't have an extra Rx channel for a separate steering channel). My rudder signal goes from the Futaba Rx to the Demon Cortex gyro via S-BUS and then a lead comes out of the gyro to the rudder. If I Y the rudder lead between the gyro and rudder and send that signal to the LG-15 steering in, will that work, or will the two gyro's fight each other?

2- Does a mating MPX connector come with the unit to attach my power supply to?

3- I have an external BEC with 6 volts going to the Rx and 7.4 or 8.4 volts to the LG-15. Will this work okay?

Thank, Rich

2. All the LGCs that I got had the multiplex connector included.

3. Your power coming from the Rxer via the gear harness runs the LGC, the brake control part of the LGC and the nose steering output to the steering servo. The Power that actually operates the gear and brakes is isolated from the power from the RXer inside the LGC. There are some pretty good instructions in the LGC's manual. The first time around you may have to read them a couple times. But the potential need for isolating the various supplied power voltage deltas is really rather simple. You can't have two different voltage levels on the same circuits, or the higher voltage source will be charging the lower one. That can cause issues.

Last edited by Len Todd; 12-30-2022 at 09:16 PM.

#524

1. It is NOT good to have two gyros working on one device. While you may get them to work together, it is highly possible that they may fight each other. Rule of thumb is to NOT have two gyros working on any one device.

2. All the LGCs that I got had the multiplex connector included.

3. Your power coming from the Rxer via the gear harness runs the LGC, the brake control part of the LGC and the nose steering output to the steering servo. The Power that actually operates the gear and brakes is isolated from the power from the RXer inside the LGC. There are some pretty good instructions in the LGC's manual. The first time around you may have to read them a couple times. But the potential need for isolating the various supplied power voltage deltas is really rather simple. You can't have two different voltage levels on the same circuits, or the higher voltage source will be charging the lower one. That can cause issues.

2. All the LGCs that I got had the multiplex connector included.

3. Your power coming from the Rxer via the gear harness runs the LGC, the brake control part of the LGC and the nose steering output to the steering servo. The Power that actually operates the gear and brakes is isolated from the power from the RXer inside the LGC. There are some pretty good instructions in the LGC's manual. The first time around you may have to read them a couple times. But the potential need for isolating the various supplied power voltage deltas is really rather simple. You can't have two different voltage levels on the same circuits, or the higher voltage source will be charging the lower one. That can cause issues.

Thanks for the useful information! That makes sense about the two gyros not being good. I just found an extra channel that I can create for steering. Then I can have the rudder and steering be separate.

#525

In the past, I too struggled with not having enough channels for running the jets. Then one day, I figured out that given the cost of the plane, why was I froggin' around with the less capable receivers. For the Jets I always get at least 14 channel equipment (usually 18 and sometimes 20 depending on availability.) I may only use 12 of them but for the small extra cost, I can later add things like Nav lights, and have landing lights turn on automatically when the gear drops, etc. Extra channels allow fine tuning the control surfaces too (e.g. Flaps, Aile differential, etc.) Also, I frequently find that when you start tying various operations to the same switches, you may need to reverse a channel that also has to be normal for another operation (e.g. gear and landing light controller.) I know that various brands and combinations of different branded components sometimes limit us. But that is when I start to question the brands I am using for jets. I also look at availability of products and usually end up keeping at least one spare of the harder to get items. A spare helps a lot when troubleshooting, and I can use it in the next build w/o waiting for it, should it be hard to get at the time.

For a gyro on the nose wheel, I just use the LGC. Even if you Y off the Rxer's rudder output to the Cortex and go directly into the LGC's Steer In, it works great. The LGC has the offset for fine tuning the steering too. There is also a gyro gain adjustment in the LGC. Or, mix to that a different channel in the Txer and feed it to the LGC. When using a buss system things can get lighter. But they also can get more complex too. I try to KISS & have fun!

For a gyro on the nose wheel, I just use the LGC. Even if you Y off the Rxer's rudder output to the Cortex and go directly into the LGC's Steer In, it works great. The LGC has the offset for fine tuning the steering too. There is also a gyro gain adjustment in the LGC. Or, mix to that a different channel in the Txer and feed it to the LGC. When using a buss system things can get lighter. But they also can get more complex too. I try to KISS & have fun!