T-One Models F22 Raptor build thread

#226

My Feedback: (20)

Paul, thanks for explaining that. It makes perfect sense. Now the question is how to fix it in the RC model application. Maybe airex is not the best material for use on the twin tails and a more robust mounting structure on to the airframe is needed.

Gary

Gary

The following users liked this post:

Looping31 (10-14-2020)

#228

My Feedback: (2)

Thanks Gary,

And this doesn't have to be at high speed or high G either. The vortices have a clear rotational frequency, and if this happens to coincide with one of the structural frequencies of the fin/ rudder, then even at low speeds and G the vortex energy will be enough to drive the fin/ rudder into resonance and eventually failure in a manner that looks like flutter.

This is avoided in full-scale by careful design and detailed analysis and ground testing, something that is unlikely to ever be done on a model.

Have a read here for more info

Aerospaceweb.org | Ask Us - F-18 Leading Edge Extension FencesThe benefits of these vortices can be appreciated when one realizes that nearly all current military aircraft designs incorporate leading edge extensions and/or canards that perform much the same function. A few examples include the F-16, AV-8B Harrier II, MiG-29, and Su-27.

Unfortunately, these vortices can also create problems, particularly on planes with twin vertical tails like the F-18. Shortly after the F-18 entered service, it was discovered that the vertical tails were suffering from cracks and fatigue. This structural damage limited the first batch of planes to a few hundred flight hours, as opposed to the several thousand flight hours the Navy required for the service life of its aircraft. The cause of the structural cracks was eventually traced back to the LEX vortices impacting on the vertical tails and creating loads the tails weren't designed to handle.

In particular, the problem was due to a phenomenon called vortex bursting. As a vortex travels downstream, it enlarges and becomes weaker. If the rotational velocity of the vortex drops low enough, the increasing pressure within the vortex causes it to lose its tornado-like structure and break apart. This bursting behavior was found to occur just ahead of the F-18 vertical tails. The resulting air flow impinged directly on the tails causing severe buffeting and structural damage. Further worsening the situation was the fact that the frequency of loads induced by vortex bursting just happened to coincide with the first natural frequency of bending in the vertical tail.

NASA conducted extensive investigation of the phenomenon using its F-18 High Alpha Research Vehicle (HARV). During testing, smoke was injected into the LEX vortex making it possible to observe its behavior during flight. The following picture shows the results of one such test. Observe the significant increase in the diameter of the vortex near the vertical tail indicating that the vortex has burst.

The fatigue and buffet problem was so significant that the Navy grounded its F-18 fleet and refused to take delivery of new production planes until a solution was found. Fearing the entire F-18 program might be cancelled as a result of this deficiency, McDonnell Douglas quickly formed a "tiger team" of engineering experts under the leadership of John Capellupo. The solution they ultimately implemented was the LEX fence described earlier. This fence is essentially another vortex generator itself. The fence creates a second unsteady vortex that interacts with the vortex created by the leading edge extension. This interaction strengthens the rotation of the main vortex so that vortex bursting is eliminated in the vicinity of the vertical tail. The repair was so effective that it not only solved the tail buffet problem but the fence also allows the F-18 to reach even higher angles of attack.

Paul

And this doesn't have to be at high speed or high G either. The vortices have a clear rotational frequency, and if this happens to coincide with one of the structural frequencies of the fin/ rudder, then even at low speeds and G the vortex energy will be enough to drive the fin/ rudder into resonance and eventually failure in a manner that looks like flutter.

This is avoided in full-scale by careful design and detailed analysis and ground testing, something that is unlikely to ever be done on a model.

Have a read here for more info

Aerospaceweb.org | Ask Us - F-18 Leading Edge Extension FencesThe benefits of these vortices can be appreciated when one realizes that nearly all current military aircraft designs incorporate leading edge extensions and/or canards that perform much the same function. A few examples include the F-16, AV-8B Harrier II, MiG-29, and Su-27.

Unfortunately, these vortices can also create problems, particularly on planes with twin vertical tails like the F-18. Shortly after the F-18 entered service, it was discovered that the vertical tails were suffering from cracks and fatigue. This structural damage limited the first batch of planes to a few hundred flight hours, as opposed to the several thousand flight hours the Navy required for the service life of its aircraft. The cause of the structural cracks was eventually traced back to the LEX vortices impacting on the vertical tails and creating loads the tails weren't designed to handle.

In particular, the problem was due to a phenomenon called vortex bursting. As a vortex travels downstream, it enlarges and becomes weaker. If the rotational velocity of the vortex drops low enough, the increasing pressure within the vortex causes it to lose its tornado-like structure and break apart. This bursting behavior was found to occur just ahead of the F-18 vertical tails. The resulting air flow impinged directly on the tails causing severe buffeting and structural damage. Further worsening the situation was the fact that the frequency of loads induced by vortex bursting just happened to coincide with the first natural frequency of bending in the vertical tail.

NASA conducted extensive investigation of the phenomenon using its F-18 High Alpha Research Vehicle (HARV). During testing, smoke was injected into the LEX vortex making it possible to observe its behavior during flight. The following picture shows the results of one such test. Observe the significant increase in the diameter of the vortex near the vertical tail indicating that the vortex has burst.

The fatigue and buffet problem was so significant that the Navy grounded its F-18 fleet and refused to take delivery of new production planes until a solution was found. Fearing the entire F-18 program might be cancelled as a result of this deficiency, McDonnell Douglas quickly formed a "tiger team" of engineering experts under the leadership of John Capellupo. The solution they ultimately implemented was the LEX fence described earlier. This fence is essentially another vortex generator itself. The fence creates a second unsteady vortex that interacts with the vortex created by the leading edge extension. This interaction strengthens the rotation of the main vortex so that vortex bursting is eliminated in the vicinity of the vertical tail. The repair was so effective that it not only solved the tail buffet problem but the fence also allows the F-18 to reach even higher angles of attack.

Paul

The following users liked this post:

Auburn02 (10-14-2020)

#230

In talks with T1 now to find a solution. Will keep you guys updated. Keith I hear you on how you think the structure is weak but have you moved a BVM F16 by the tail? It feels like its going to break off its so flimsy. I still feel it does not matter how strong the structure is if it flutters its going to come apart period. You might make something stronger but it will just break the next weakest link. They key is preventing the flutter.

For the glue used. Its not the glue its the airX that comes apart. When you stress airX the formers will pull the airX apart making it look like its not glued. I have done countless repairs for people with airX and it does the same thing every time. AirX is super light and a great advancement in this hobby getting the weight down in these bigger planes but its not as strong as a normal glass hysol and wood former construction. At the end of the day though its a flutter issue in my opinion not a structure issue. We will see what T1 says. We also have Jeff helping out with this and with his background being an aeronautical engineer its good having his help. Barry I am sure will also be helping out. Both of us told T1 on day 1 that the rudder on the F22 needs to be super strong with no play due to flutter since we both had issues with our older F22s. He had a few jet legend F22s and I had the yellow. Flutter was always an issue on them. The yellow I flew and sold after over 400 flights ended up getting rudder flutter with its new owner and crashing.

For the glue used. Its not the glue its the airX that comes apart. When you stress airX the formers will pull the airX apart making it look like its not glued. I have done countless repairs for people with airX and it does the same thing every time. AirX is super light and a great advancement in this hobby getting the weight down in these bigger planes but its not as strong as a normal glass hysol and wood former construction. At the end of the day though its a flutter issue in my opinion not a structure issue. We will see what T1 says. We also have Jeff helping out with this and with his background being an aeronautical engineer its good having his help. Barry I am sure will also be helping out. Both of us told T1 on day 1 that the rudder on the F22 needs to be super strong with no play due to flutter since we both had issues with our older F22s. He had a few jet legend F22s and I had the yellow. Flutter was always an issue on them. The yellow I flew and sold after over 400 flights ended up getting rudder flutter with its new owner and crashing.

#232

My Feedback: (14)

Looking forward to the end all solution here, as I would love to own this jet when all the kinks are worked out. In the meantime I also affirm that a stronger vertical fin/ attach structure is prudent. Control surface Flutter can cause ridged structures to fail, yet flimsy structures can cause flutter with or without a control surface present.

from the pictures I see, it appears as if the entire fin is subject to flutter, perhaps not originating from the control surface itself. The ridgid ďzero playď hardware now included should solve the control surface flutter but this may just be a bandaid and delay the occurrence of the entire stab fluttering. A non airex stab made with CF cloth on a 45 bias would make these stabs stiff as a board. You could even go with 1/8 aircraft ply structure to prototype. Looks like t-1 has a little testing to do...

from the pictures I see, it appears as if the entire fin is subject to flutter, perhaps not originating from the control surface itself. The ridgid ďzero playď hardware now included should solve the control surface flutter but this may just be a bandaid and delay the occurrence of the entire stab fluttering. A non airex stab made with CF cloth on a 45 bias would make these stabs stiff as a board. You could even go with 1/8 aircraft ply structure to prototype. Looks like t-1 has a little testing to do...

#233

Ok guys quick update.

Work is progressing. I have come up with a design and built it up to send pictures to T1 to get their opinion. Lucky I had a spare fin from the prototype to cut on.

T1 also has a design made up. So Barry, T1, Jeff, and I are all talking about the best solution. I am pushing to get this going quicker.

What I can tell you is its no longer a direct drive on both designs. On mine it will greatly increase servo torque and that will also lessen the servo gear lash play at the rudder. Mine is a little harder to implement though. So we will see how they want to proceed. Just know we are all working to get this done.

Work is progressing. I have come up with a design and built it up to send pictures to T1 to get their opinion. Lucky I had a spare fin from the prototype to cut on.

T1 also has a design made up. So Barry, T1, Jeff, and I are all talking about the best solution. I am pushing to get this going quicker.

What I can tell you is its no longer a direct drive on both designs. On mine it will greatly increase servo torque and that will also lessen the servo gear lash play at the rudder. Mine is a little harder to implement though. So we will see how they want to proceed. Just know we are all working to get this done.

The following users liked this post:

Remco45 (10-29-2020)

#234

Ok guys quick update.

Work is progressing. I have come up with a design and built it up to send pictures to T1 to get their opinion. Lucky I had a spare fin from the prototype to cut on.

T1 also has a design made up. So Barry, T1, Jeff, and I are all talking about the best solution. I am pushing to get this going quicker.

What I can tell you is its no longer a direct drive on both designs. On mine it will greatly increase servo torque and that will also lessen the servo gear lash play at the rudder. Mine is a little harder to implement though. So we will see how they want to proceed. Just know we are all working to get this done.

Work is progressing. I have come up with a design and built it up to send pictures to T1 to get their opinion. Lucky I had a spare fin from the prototype to cut on.

T1 also has a design made up. So Barry, T1, Jeff, and I are all talking about the best solution. I am pushing to get this going quicker.

What I can tell you is its no longer a direct drive on both designs. On mine it will greatly increase servo torque and that will also lessen the servo gear lash play at the rudder. Mine is a little harder to implement though. So we will see how they want to proceed. Just know we are all working to get this done.

#236

My early version does not even have the screw hole (and of course no screw) for the securing plate on the fuselage side for the vertical stabs, just plain epoxy bond of ply to aluminium. Now it's an awkward position and angle to drill that hole. Stiffening the vertical stabs will in high probability transfer any vortice vibrations to the fuse if it is the root cause. Hope the factory will consider how to reinforce that area as well.

#238

Gunradd,

Will the necessary updated part(s) to correct the rudder issue(s) be made available to all current owners of the T-1 F-22? Really been looking forward to getting this plane in the air, but will patiently wait until a viable solution to the rudder issue is found.

Will the necessary updated part(s) to correct the rudder issue(s) be made available to all current owners of the T-1 F-22? Really been looking forward to getting this plane in the air, but will patiently wait until a viable solution to the rudder issue is found.

I donít have any plans to stop flying the demo bird though with the stock setup. I donít fly it fast I like to fly it scale so itís held up fine to my flying style. When the new stuff is out I will switch it though.

#241

#244

here are a few short videos from flying over the weekend. F22 is flying perfect!! Love this plane. I am not sure if its the smoothflight gyro or the plane but this plane is the most solid scale jet I have flown.

First will be a minimum radius turn.

Next we have a bomb bay open pass

Fast pass

Landing

First will be a minimum radius turn.

Next we have a bomb bay open pass

Fast pass

Landing

The following users liked this post:

Remco45 (11-23-2020)

#245

4 more flights on the raptor yesterday! She is really flying nice. Filling out my TopGun paper work today. Going to enter the F22 in the expert class so she will get static judging.

will start getting my paper work together and getting her detailed up.

still trying to pick the best takeoff with or without flaps. Right now im thinking I like no flaps takeoffs.

will start getting my paper work together and getting her detailed up.

still trying to pick the best takeoff with or without flaps. Right now im thinking I like no flaps takeoffs.

#249

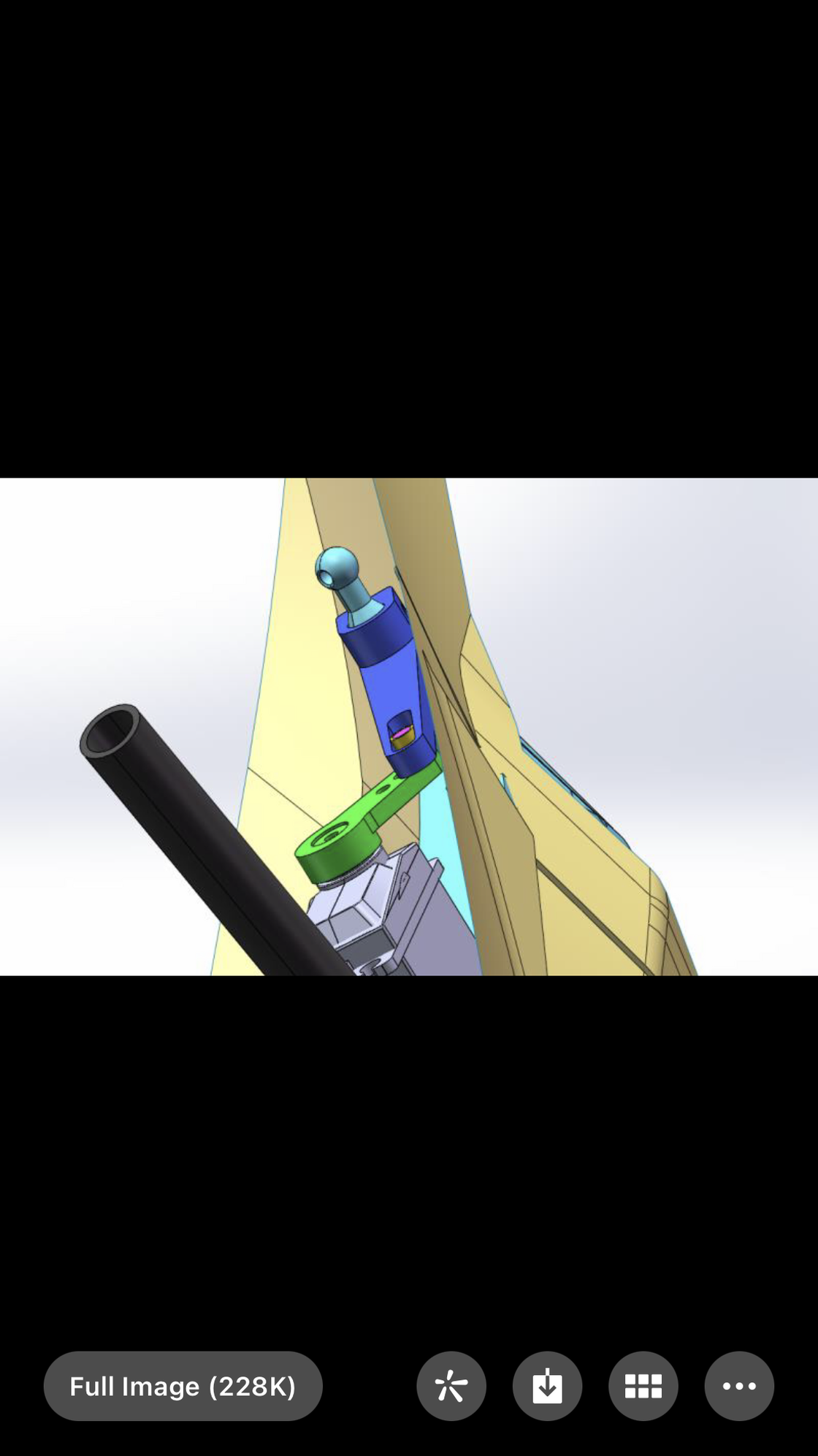

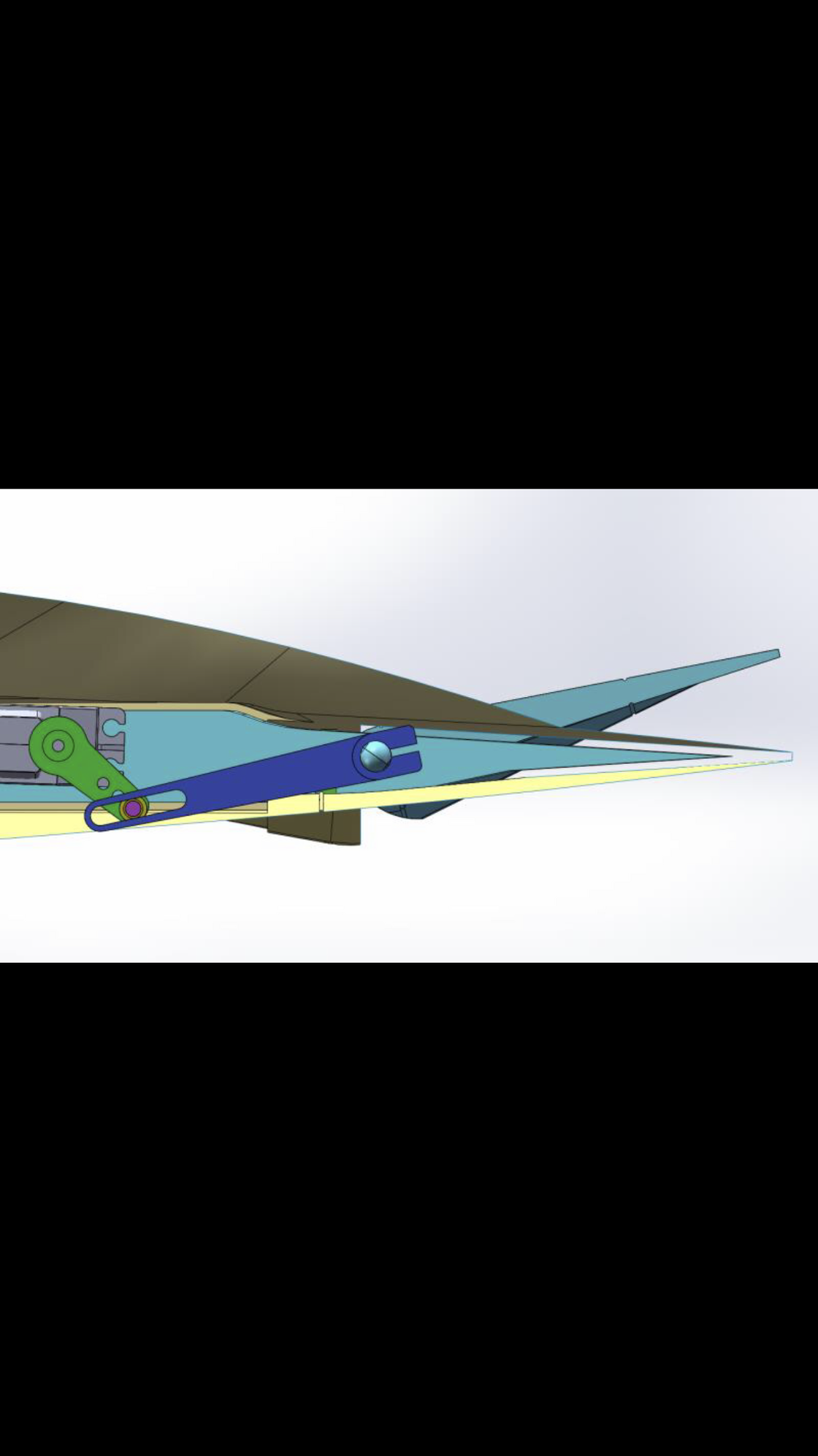

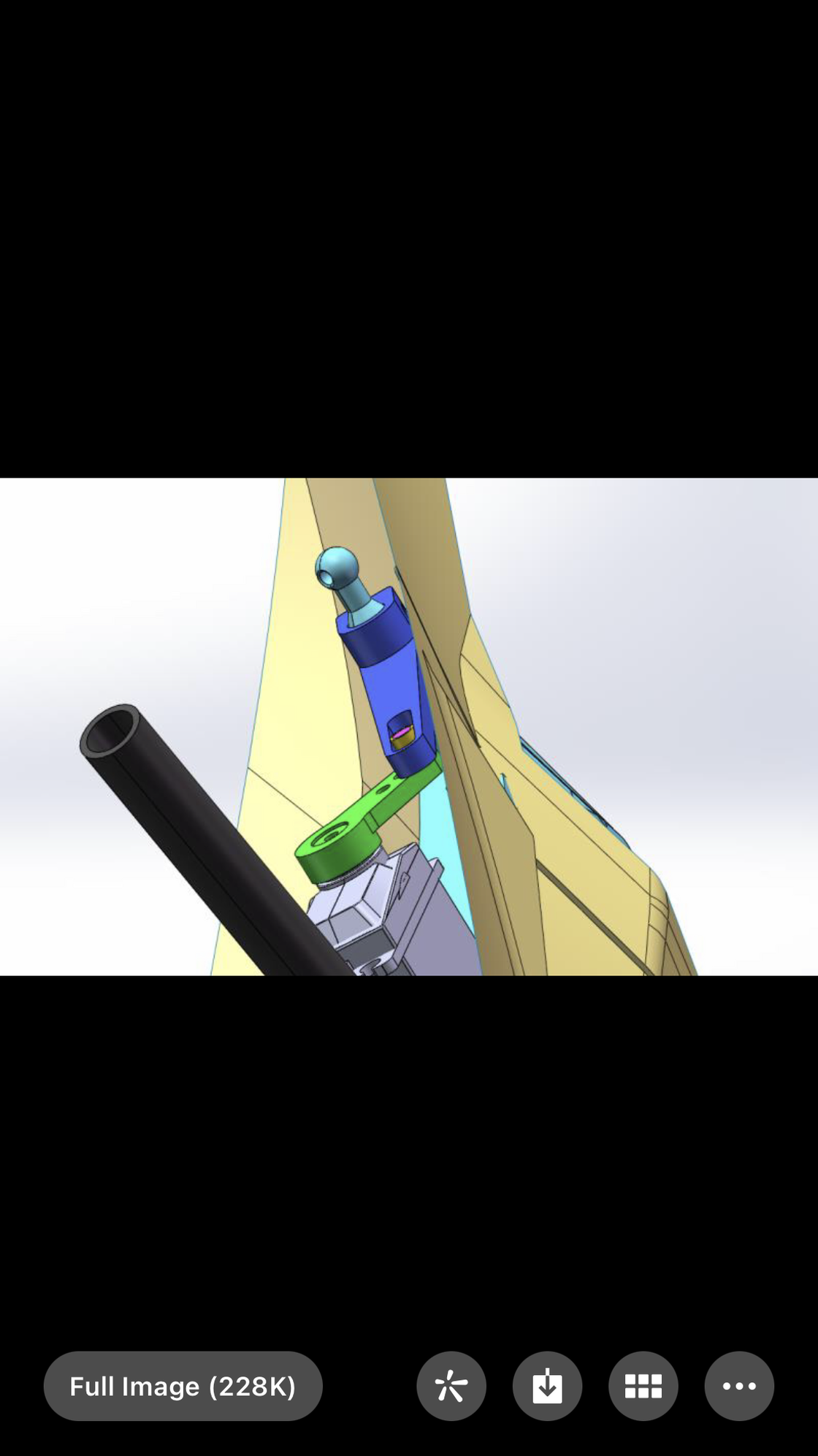

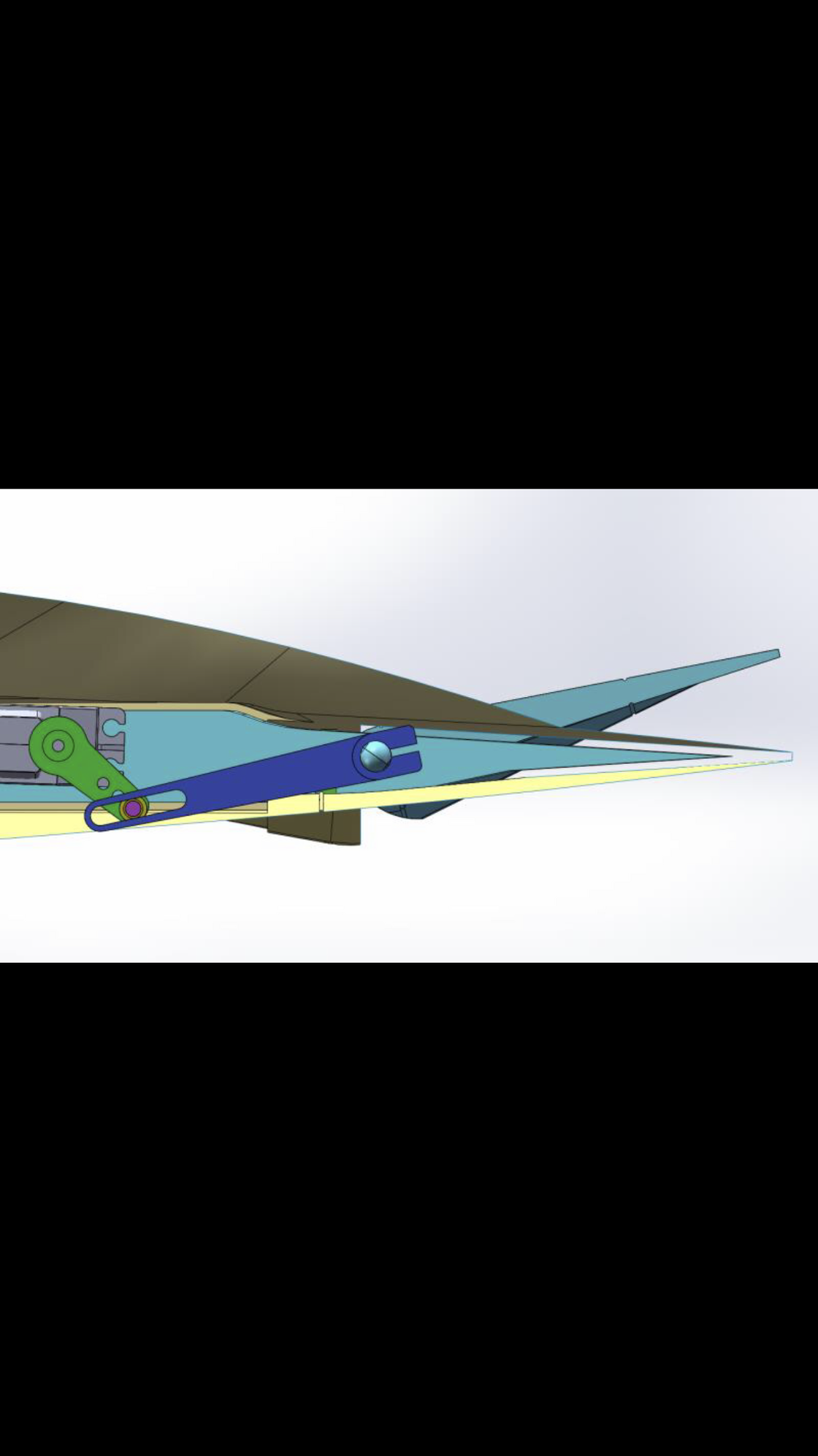

Update on the verticals and rudders. The factory made a full carbon set for a friend of mine with longer linkages. So thatís an option.

I still want them to change the servo location to what I will show in these pics. It will greatly increase torque and have limit the play along with stay hidden. The issue is getting enough throw. So work is getting done just trying to find the best solution still.

in the mean time I have 38 flights now on the stock setup no issues.

I still want them to change the servo location to what I will show in these pics. It will greatly increase torque and have limit the play along with stay hidden. The issue is getting enough throw. So work is getting done just trying to find the best solution still.

in the mean time I have 38 flights now on the stock setup no issues.

The following users liked this post:

Remco45 (12-22-2020)

#250

I received these same pictures over a week ago when you friend received them. He mentioned having to pay for them, is the factory going to charge for new rudders for the current customers?