Welcome to Club SAITO !

My Feedback: (6)

I have one Enya 4 cycle in my stash its a NIB .46 4C Type II. The previous owner bought it and never ran it. I'm not sure if he ever took it out of the box.

Yeah, a fella has to be careful about how much material he's milling off the deck. Easy to go too far, but a shim will always fix it. I machined my HC 82 in three stages, measured the CR and ran it each time on my 15% fuel. I could have gone farther with it but I achieved my goal, to make it reach rated hp and handle well. The CR ended up at 11.75:1. I've tried to make it throw props by leaning but it won't, the rpm just sags.

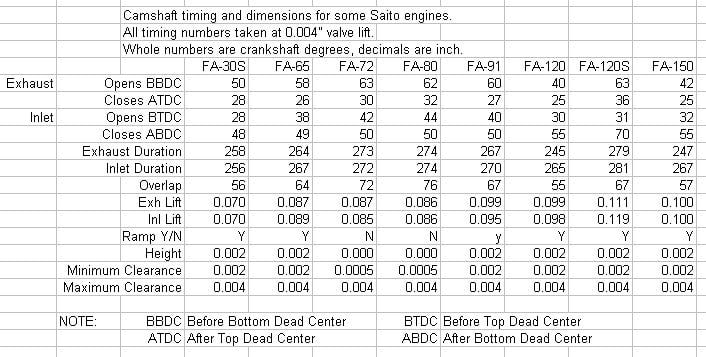

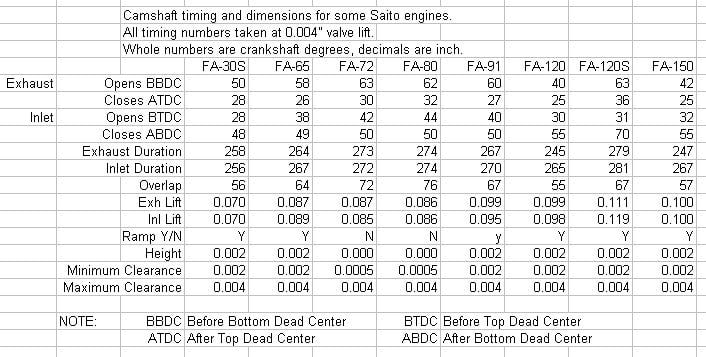

An interesting cam profile chart Bill Robison developed way back.

These old cams are no longer sold as new parts. The sai6535a cam is what is sold now to replace the originals (fa-62b thru fa-115 and fa125). According to Bill the sai6535a cam profile matches the fa72 shown in the chart above and is the cam used in the "high cam" series engines.

See old thread here: does your SAITO idle low and nice?

This begs to ask, at what point did saito go to the high cam series?

Does anyone have some boxes for fa65's with some saying "high cam" and some that don't?

What about the the fa91S, are they all "high cam" engines?

These old cams are no longer sold as new parts. The sai6535a cam is what is sold now to replace the originals (fa-62b thru fa-115 and fa125). According to Bill the sai6535a cam profile matches the fa72 shown in the chart above and is the cam used in the "high cam" series engines.

See old thread here: does your SAITO idle low and nice?

This begs to ask, at what point did saito go to the high cam series?

Does anyone have some boxes for fa65's with some saying "high cam" and some that don't?

What about the the fa91S, are they all "high cam" engines?

Last edited by Glowgeek; 03-20-2020 at 05:06 AM.

Thanks for the fa80 cam housing Gary, iirc no cam included. According to Bill's measurements the fa80 cam was almost identical to the fa72 (sai6535a) which is currently available. It may actually be identical as it's very easy to mis-measure by a degree or two.

Last edited by Glowgeek; 03-20-2020 at 05:14 AM.

A degree or two is well inside the measurement tolerance for even a good tech. Add to that, well inside the factory repeatability as well. I should have said "housing". The batch of big block Saito parts that I sent to Dave had both type cams (there were actually at least three) for the big block. The Fathead had a cam of its own.

I have a couple of brand new "reverse rotation" cams as well and plan to install and run one this summer.

I have a couple of brand new "reverse rotation" cams as well and plan to install and run one this summer.

Last edited by Jesse Open; 03-20-2020 at 05:36 AM.

Lonnie,

The local guy is still needing a rear cover for tha single tab 45 Saito. Can you send me one? I will mail you a reverse rotation cam in exchange.

The local guy is still needing a rear cover for tha single tab 45 Saito. Can you send me one? I will mail you a reverse rotation cam in exchange.

My Feedback: (5)

Finally made it to the saito radial club! Might have to take the DLE 55 off my Corsair and put this bad boy on it. Very excited to hear it run!

I was thinking about finding a Stearman,T-6 or T-28 to put it in, if I do not put on the Corsair.

I was thinking about finding a Stearman,T-6 or T-28 to put it in, if I do not put on the Corsair.

The following users liked this post:

rowdog_14 (03-24-2020)

The following users liked this post:

rowdog_14 (03-24-2020)

Maybe some day I will build a giant scale Corsair from the parts I made. It calls for a radial, it must have a radial. I just can't AFFORD a radial!  For now the parts I am cutting are to proof out the kit. I am almost done, just have some fine tuning to do on some parts for a better fit. Need to remove some slop for slots due to the plywood being metric, and the plans being inch. So have to tighten is all up .004 to .008 inch all around. I also have to allow for the burn off from the laser, which is .003 for the beam and is dead center of the line, so adding in another .0015-.002 depending on the wood and speed/power. Balsa is pretty tight, but the 1/4" and birch ply requires a lot of power at a slow speed to get a complete cut, which chars the wood a bit.

For now the parts I am cutting are to proof out the kit. I am almost done, just have some fine tuning to do on some parts for a better fit. Need to remove some slop for slots due to the plywood being metric, and the plans being inch. So have to tighten is all up .004 to .008 inch all around. I also have to allow for the burn off from the laser, which is .003 for the beam and is dead center of the line, so adding in another .0015-.002 depending on the wood and speed/power. Balsa is pretty tight, but the 1/4" and birch ply requires a lot of power at a slow speed to get a complete cut, which chars the wood a bit.

Machining is so much easier than laser cutting, at least you know when you zero out, a .001 cut is .001. LOL

For now the parts I am cutting are to proof out the kit. I am almost done, just have some fine tuning to do on some parts for a better fit. Need to remove some slop for slots due to the plywood being metric, and the plans being inch. So have to tighten is all up .004 to .008 inch all around. I also have to allow for the burn off from the laser, which is .003 for the beam and is dead center of the line, so adding in another .0015-.002 depending on the wood and speed/power. Balsa is pretty tight, but the 1/4" and birch ply requires a lot of power at a slow speed to get a complete cut, which chars the wood a bit.

For now the parts I am cutting are to proof out the kit. I am almost done, just have some fine tuning to do on some parts for a better fit. Need to remove some slop for slots due to the plywood being metric, and the plans being inch. So have to tighten is all up .004 to .008 inch all around. I also have to allow for the burn off from the laser, which is .003 for the beam and is dead center of the line, so adding in another .0015-.002 depending on the wood and speed/power. Balsa is pretty tight, but the 1/4" and birch ply requires a lot of power at a slow speed to get a complete cut, which chars the wood a bit. Machining is so much easier than laser cutting, at least you know when you zero out, a .001 cut is .001. LOL

Depends on what kind of machining you are talking about. As in is there a computer involved etc. Most of the work involving computers goes to folks with limited skills.

We do both at work. The laser operators are mostly guys that came from the closed up painting department. The taught them how to run a 2D laser, cutting out flat blanks so they wouldn't have to lay them off . That was a union deal. We only have three of the flat lasers. The other 12 cut out full size 3D parts.

Don't take any of that the wrong way.

You are indeed doing a very nice job with the laser, in any event. A lot of work, well done.

We do both at work. The laser operators are mostly guys that came from the closed up painting department. The taught them how to run a 2D laser, cutting out flat blanks so they wouldn't have to lay them off . That was a union deal. We only have three of the flat lasers. The other 12 cut out full size 3D parts.

Don't take any of that the wrong way.

You are indeed doing a very nice job with the laser, in any event. A lot of work, well done.

Last edited by Jesse Open; 03-22-2020 at 03:22 AM.

The following users liked this post:

acdii (03-21-2020)

My Feedback: (6)

i agree with Glowgeek! I got to say you are working very hard to get it right and investing the time and money to get the best cut you can. I hope all the work is enjoyable for you too!

Thanks.

Metal cutting with a laser is easy, metal doesn't vary in density like wood, so when you put a board in and its cutting through and then hits a hard spot it can flash and burn more wood and not cut through. Also you don't cut metal on a CO2 laser, need a fiber laser or other type of wavelength. CO2 just bounces off most metals. It can etch anodized or painted aluminum, but can't cut it.

I should try another engraving now that I have better optics and see how it comes out.

Metal cutting with a laser is easy, metal doesn't vary in density like wood, so when you put a board in and its cutting through and then hits a hard spot it can flash and burn more wood and not cut through. Also you don't cut metal on a CO2 laser, need a fiber laser or other type of wavelength. CO2 just bounces off most metals. It can etch anodized or painted aluminum, but can't cut it.

I should try another engraving now that I have better optics and see how it comes out.

Seems like from what I've read from the laser kit sites that they require builders to laminate sheets together to create thicker stock. Apparently you're not the only only one having problems with burnt wood and dimensional tolerance issues.