What is the most flexible pushrod system?

#1

Member

Thread Starter

My Feedback: (1)

Join Date: Mar 2005

Location: Portage,

IN

Posts: 76

Likes: 0

Received 0 Likes

on

0 Posts

Hello, I am having trouble hooking up my throttle controls on my twin engine airplane. I bought the Great Planes flexible pushrod (wire that runs through a housong). But by the time I make all of the turns needed to get to my engines control arm, the force needed to push and pull the wire is very tight. I need something that can be turned and bent without binding up or getting tougher to operate. Thanks so much!!!

#2

RCU Forum Manager/Admin

My Feedback: (9)

Go to your local hardware store and buy some graphite dry lubrication. Squirt it inside pushrod housing, then work the pushrod so the graphite works all the way down the tubing. This will loosen up the pushrod and then you shouldn't have any problems with it.

Hope this helps

Ken

Hope this helps

Ken

#3

My Feedback: (24)

ORIGINAL: captnem

I bought the Great Planes flexible pushrod (wire that runs through a housong).

I bought the Great Planes flexible pushrod (wire that runs through a housong).

#7

Member

Join Date: Oct 2003

Location: Perth, AUSTRALIA

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

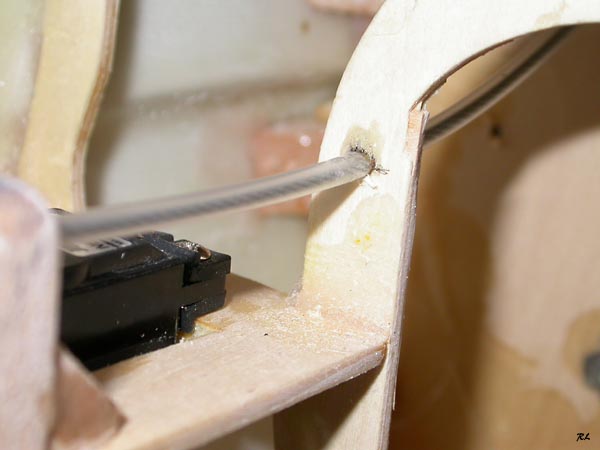

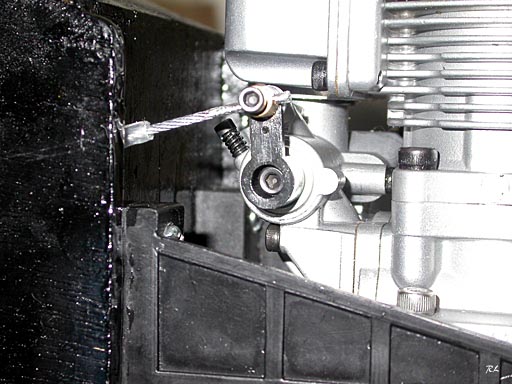

If you are looking at Richard L's pics he doesn't have any troubles with that set up! It's because he is using that particular Dubro cable. It is very flexible and has surprisingly little binding even with quite acute bends. It works a treat as he has shown.

#8

My Feedback: (24)

Correct, I do not have any troubles with the Dubro braided cable set up. It takes very little effort to move the cable. Similarly, the braided cables inside bicycle brake lines have little resistance even though the lines are long. The engines in the pictures are four strokes with the throttle arms close to the firewall.

#9

Join Date: Dec 2001

Location: Upplands Vasby, SWEDEN

Posts: 7,816

Likes: 0

Received 4 Likes

on

4 Posts

Hi!

Sorry! But your set-up /design must be wrong!

I try to use the thinnest Sullivan wire whenever I set up the throttle as this is the lightest throttle wire available...but it is very important that you have a good design otherwise the wire will bend or get stuck.

Show us some pictures of your set-up please.

Regards!

Jan K

Sweden

Sorry! But your set-up /design must be wrong!

I try to use the thinnest Sullivan wire whenever I set up the throttle as this is the lightest throttle wire available...but it is very important that you have a good design otherwise the wire will bend or get stuck.

Show us some pictures of your set-up please.

Regards!

Jan K

Sweden

#10

Senior Member

My Feedback: (1)

Richar L. Is right!

If you use the sullivan Golden cable (it's braded) or the Dubro Cable (braded) your problems will go away. If you already have the sheathing routed your half way there just get some of the appropriate diameter cable (braded) and run it.

Also if using quick links at the servo make you nervous, just put a Z bend in the cabe, then tin it with solder and install in the arm as you would a Z bent rod.

Darren

If you use the sullivan Golden cable (it's braded) or the Dubro Cable (braded) your problems will go away. If you already have the sheathing routed your half way there just get some of the appropriate diameter cable (braded) and run it.

Also if using quick links at the servo make you nervous, just put a Z bend in the cabe, then tin it with solder and install in the arm as you would a Z bent rod.

Darren

#12

Senior Member

My Feedback: (2)

Join Date: Jun 2002

Location: Mt. Morris, MI

Posts: 1,151

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: The Ghost

Why not just use 2 micro servos for the throttles. Then mix in the trans, Problem solved.

Cheers.

Why not just use 2 micro servos for the throttles. Then mix in the trans, Problem solved.

Cheers.

#13

Senior Member

Join Date: Apr 2005

Location: Wpg,

MB, CANADA

Posts: 2,162

Likes: 0

Received 0 Likes

on

0 Posts

HERE`S A TIP,THAT FOLKS MAY NOT KNOW....I purchased a DU-BRO throttle kit for my CORSAIR (good kit)but didn`t use any of the fittings that came with it (pictured assembly)..I now buy a bunch of various fittings, from LHS.(to keep on hand). Also the nyrod tube (3 ft lengths)I use that to route cables, antena wires,lots of uses for it,and is cheap.FOR the braided cable, I now buy stainless steel braided cable at the hardware store (12 feet @ a time). THESE parts are IDENTICLE to the cable,and housing,that is supplied in the DUBRO kit,and the cost is minimal..If a lube is needed(graphite)and not available,grab a carpenter pencil(any pencil),its graphite too.Rub it on the braided cable, and assemble your ends. Advantage is you`ll always have the materials on hand to ,build cables up to 3 feet in length,and not have to wait for the store to open..A few pics ,of my bulk supplies , beside the kit supplies..DAVE B.

#14

Join Date: Mar 2004

Location: UlladullaNSW, AUSTRALIA

Posts: 1,868

Likes: 0

Received 0 Likes

on

0 Posts

Believe it or not, there are a few of us neanderthals who do not own, nor do we particularly lust to own, a computer radio.

Just use a Y lead and adjust the links

Cheers.

#15

Banned

My Feedback: (4)

Join Date: Jul 2005

Location: suncook, NH

Posts: 391

Likes: 0

Received 0 Likes

on

0 Posts

sullivan used to make two sizes of braided cable one was about 1/16 inch diameter the other was about half that size it came with the neccasary threaded couplers to be sodered on for clevises.i used this on a hobby hangar p-47 for airlerons with out any problems with flexing as the outer sheating was supported every few inches by ribs..the larger cable could not make the tight radius in the small wing chord at the tips with out binding.at least using the cable correctly eliminates most of the slop found in bellcrank type setups.

#18

Oh, I don't know. I was reading through this thread not paying any attention to the date on it and was wondering the exact same thing about soldering some sort of end onto that braided stainless steel cable. Plus, if it hadn't been for the guy who reopened it, I wouldn't have known that the Dubro flex cable was really hardware braided cable in disguise.

carl

carl

#19

Models are timeless. Good hints, even 15 years ago. I bought some hardware store cable probably 15 years ago that is stainless steel. I can't solder it either. If the OP is still flying planes, I would bet that he has a computer radio by now :-) Farther back in time when there was a Hobby Lobby in Tennessee, they sold bulk hardware that used plastic air line tubing and some flex cable that could be soldered. That was in the early 1980s IIRC. Not sure how tight of a bend it could go though.

#20

My Feedback: (158)

Well how I do it, 15 year old thread or not

Clean the end with some acetone, sand it lightly to scuff it up some,, dunk it in a good solder paste,

I take a drill bit and scratch up the inside of the coupling fitting,, also adding solder paste inside

Slide together and heat up with a good soldering iron,, sweat in some solder the same way you solder copper plumbing fittings

Pretty easy actually,, ,Good luck

Clean the end with some acetone, sand it lightly to scuff it up some,, dunk it in a good solder paste,

I take a drill bit and scratch up the inside of the coupling fitting,, also adding solder paste inside

Slide together and heat up with a good soldering iron,, sweat in some solder the same way you solder copper plumbing fittings

Pretty easy actually,, ,Good luck

#22

Typically, the process of galvanizing is dipping ferrous metal into molten zinc which forms a sacrificial coating. To galvanize a cable would be the equivalent to tinning a wire with solder and if you did that, the cable would no longer be flexible!

Some cables may be plated however, but whether plated or just plain stainless, with correct preparation and flux, either can be soldered easily.

#23

I tried a couple fluxes on the stainless 1/16" cable from TSC and the solder would not touch it. Other stainless cookware that I have tried to solder would not stick either. I have welded stainless with no problems at all. Actually I used stainless welding rod on mild steel for a long time and prefer it. (until I needed to buy more) The cable from Hobby Lobby had a copper or brass plating and soldered very well, much like the Sullivan and Dubro.

#24

I tried a couple fluxes on the stainless 1/16" cable from TSC and the solder would not touch it. Other stainless cookware that I have tried to solder would not stick either. I have welded stainless with no problems at all. Actually I used stainless welding rod on mild steel for a long time and prefer it. (until I needed to buy more) The cable from Hobby Lobby had a copper or brass plating and soldered very well, much like the Sullivan and Dubro.

There's one more factor here that might bear some consideration and that is the formula of the solder itself. There are quite a few different formulations of solder out there, for instance there's 50/50 lead tin or other proprtions. Some solder contains silver or antimony while other blends contain no lead and so on. I personally haven't noticed any huge differences between blends of solder but it COULD indeed matter depending on application. In my own experience, I've found solder that was lead free to be a bit more troublesome to use, but I can't be more specific about the differences between solder formulations.

It may be that one formula of solder will work much better than another for a specific application. I've also found that one store seldom has a good variety of solder types although they are readily available from other sources.

Last edited by airsteve172; 04-09-2020 at 08:06 PM.

#25

I think I used the Stay Brite liquid, and a Kester? paste and liquid (acid I think) It was quite a while ago. It is probably still lurking around somewhere 30 years later. I should try again. It was a nice quality cable. I would like to try something more flexible on an old Dumas Giant Swamp Buggy that was having throttle issues. Maybe a welding supply place is better for solder and acid flux. I want to do some aluminum brazing again. Was never satisfied with that stuff either. Can't do things at work since I retired 10 years ago.